Deep Draw Metal Stamping

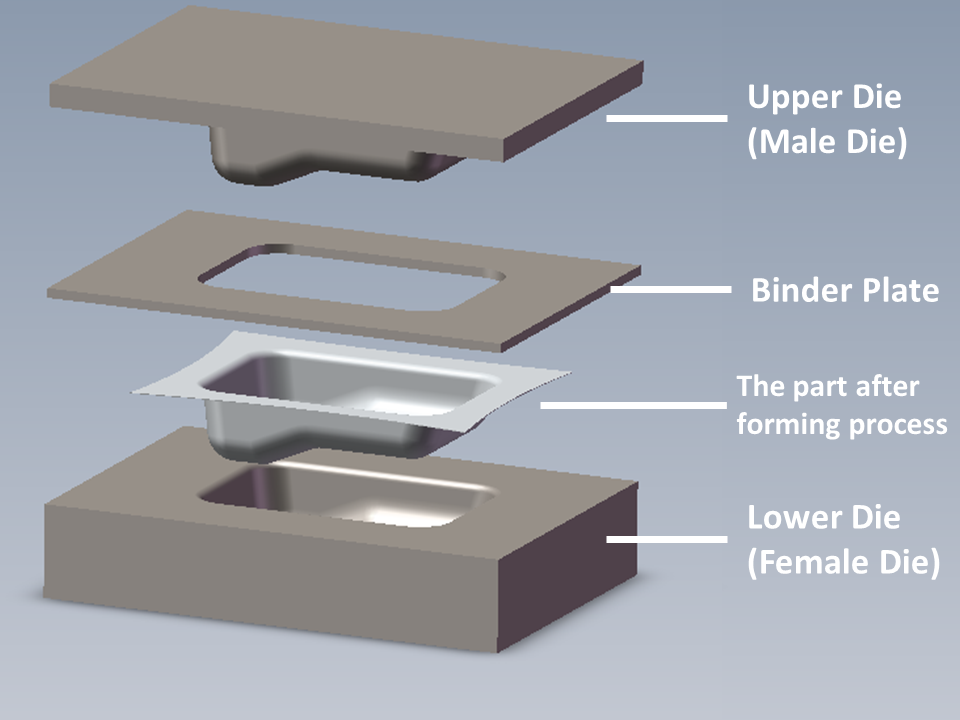

Deep Draw Metal Stamping - Web charles richter is a worldwide manufacturer of deep drawn metal stampings, offering custom metalwork services for nearly all applications across many industry. Not only is it important to ensure that the die. Web hudson technologies is a leading u.s. Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. This method often results in less waste, as the metal is stretched and formed rather than cut away. Deep drawn stamping uses a greater amount of the base material than other metal forming. Web specialists in deep drawing, deep draw metal stamping & deep drawn enclosures. Web advantages of deep draw stamping complex shapes: Web deep draw metal stamping is an ideal process for cylindrical or axisymmetric parts that can be manufactured quickly to tight tolerances. Web welcome to our deep draw shop. The stamping action in deep drawing is always accompanied by other metal forming techniques within the press. Anatomy of deep drawn stamping. Drawing is a metal forming process in which the flow of material over a punch or into a cavity is controlled. Examples of typical deep drawn components include cans, housings, and other containers. This method often results in. Deep drawn stamping uses a greater amount of the base material than other metal forming. This is the fifth in a series of articles presenting the fundamentals of stamping die design and construction. Types of deep drawing parts Deep draw metal stamping is a processing method for making open hollow parts from flat material or hollow process parts by using. Deep draw stamping excels in producing intricate, deep, and complex shapes that might be challenging for. [1] it is thus a shape transformation process with material retention. Web welcome to our deep draw shop. Deep drawn stamping uses a greater amount of the base material than other metal forming. Forcing part of the components diameter to extend from the original. Deep drawn stamping uses a greater amount of the base material than other metal forming. Not only is it important to ensure that the die. Web deep draw metal stamping is an ideal process for cylindrical or axisymmetric parts that can be manufactured quickly to tight tolerances. Drawing is a metal forming process in which the flow of material over. Web the hines group is a u.s. Deep draw stamping excels in producing intricate, deep, and complex shapes that might be challenging for. We provide superior value when compared to suppliers in china, india, or mexico. Displacing the material to create smaller or larger diameters than the part’s original diameter. Not only is it important to ensure that the die. Drawing is a metal forming process in which the flow of material over a punch or into a cavity is controlled. Web premier metal works, inc. Cutting a round or shaped section of metal from the draw component. Forcing part of the components diameter to extend from the original shape. Here at pmp, we tailor our deep drawing expertise in. Cutting a round or shaped section of metal from the draw component. Web advantages of deep draw stamping complex shapes: Forcing part of the components diameter to extend from the original shape. Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Planning the part design every deep draw metal stamping process starts with. In deep drawing, the product’s depth is two or more times greater than its width or diameter. Web deep draw stamping d&h industries offers a broad range of press forming capabilities and extensive experience stamping complex metal part designs with drawn features. Deep drawn stamping uses a greater amount of the base material than other metal forming. Here at pmp,. Planning the part design every deep draw metal stamping process starts with planning the part design. Serving global customers in aerospace, medical, battery, electronic and industrial markets for. Cutting a round or shaped section of metal from the draw component. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: This. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped cup or cylinder. Planning the part design every deep draw metal stamping process starts with planning the part design. Web welcome to our deep draw shop. Here at pmp, we tailor our. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. [1] it is thus a shape transformation process with material retention. Deep drawn stamping uses a greater amount of the base material than other metal forming. The stamping action in deep drawing is always accompanied by other metal forming techniques within the press. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Web deep draw metal stamping is an ideal process for cylindrical or axisymmetric parts that can be manufactured quickly to tight tolerances. Not only is it important to ensure that the die. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped cup or cylinder. Types of deep drawing parts The benefit of using deep drawn metal stampings is the creation of a seamless metal component. Web advantages of deep draw stamping complex shapes: The mold for deep drawing is been called deep drawing die. Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Serving global customers in aerospace, medical, battery, electronic and industrial markets for. Web deep draw stamping d&h industries offers a broad range of press forming capabilities and extensive experience stamping complex metal part designs with drawn features.

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

Deep Draw Metal Stamping Getting Started

RAO Deep Draw & Metal Stamping Sheet Metal Forming Deep Drawn

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep Draw Stamping Precision Metal StampingSheet Metal Fabrication

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

Tools for Deep Draw Metal Stampings Important Facts by PMP

Web Deep Drawn Stamping Process The Process.

We Provide Superior Value When Compared To Suppliers In China, India, Or Mexico.

The Three Steps To Deep Draw Metal Stamping Are As Follows:

Web Charles Richter Is A Worldwide Manufacturer Of Deep Drawn Metal Stampings, Offering Custom Metalwork Services For Nearly All Applications Across Many Industry.

Related Post: