Deep Draw Stamping

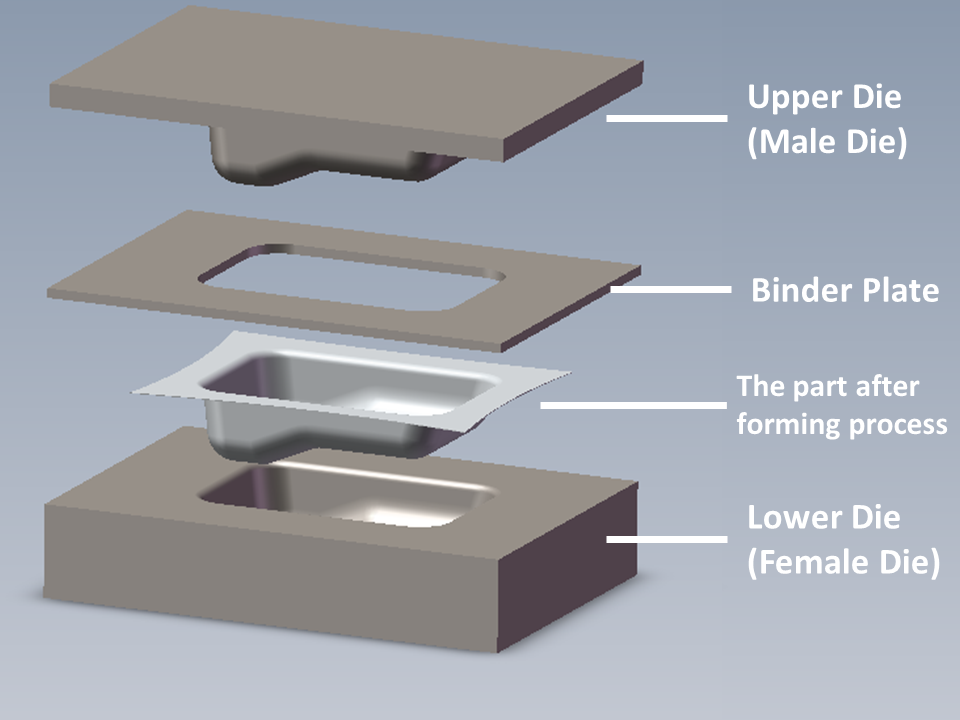

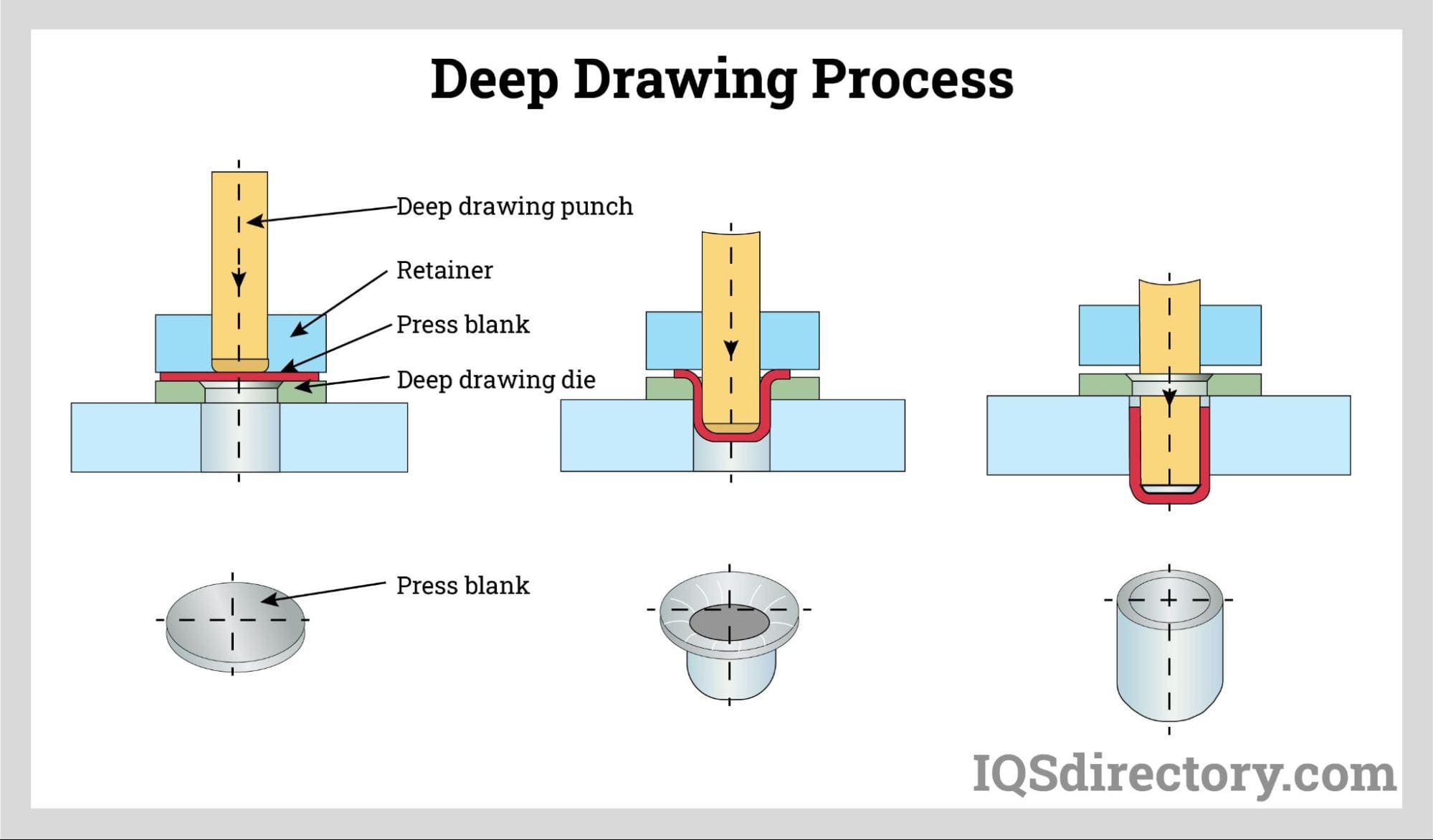

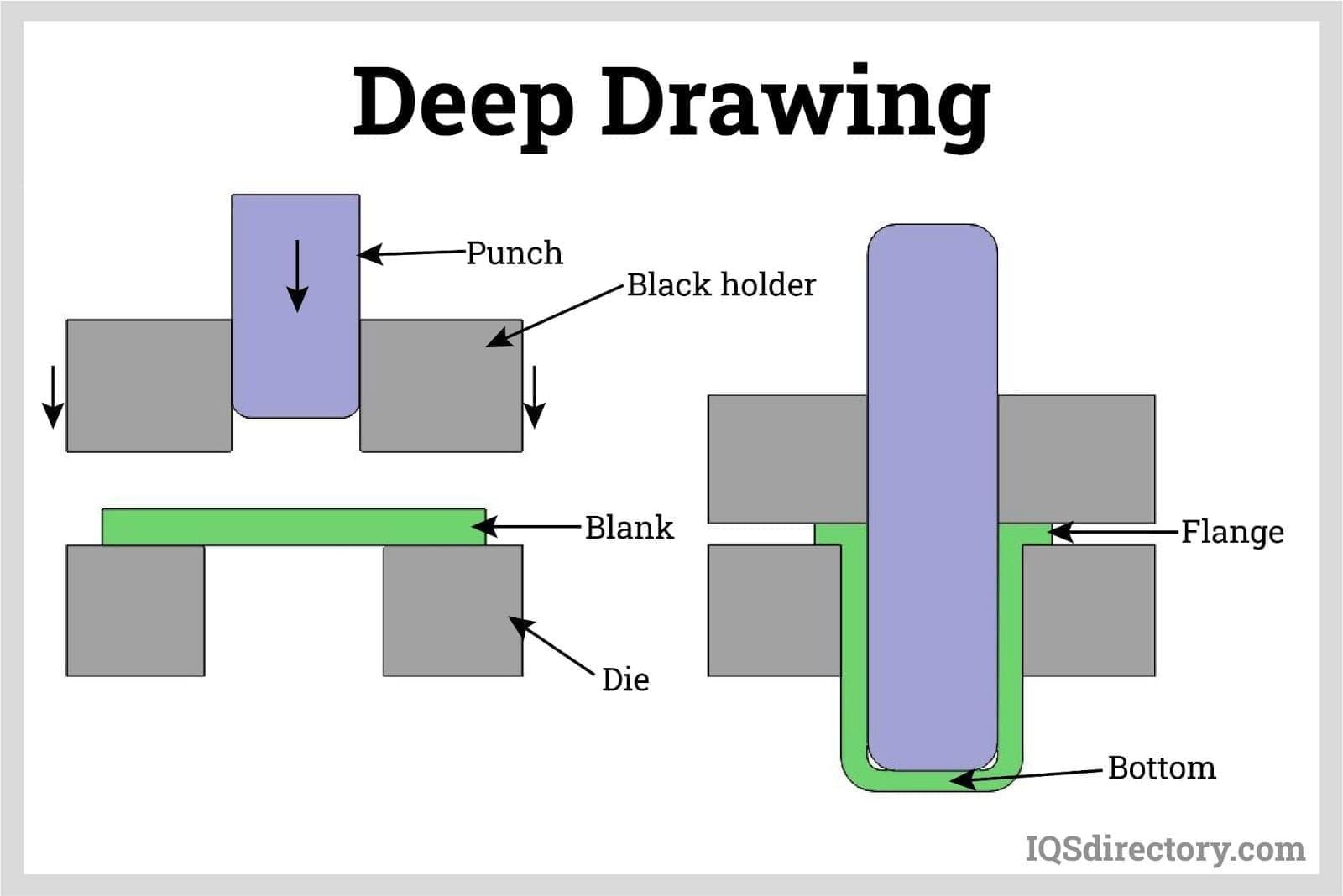

Deep Draw Stamping - Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. The most prominent benefit is that the unit cost is decreased considerably when unit count increases. Key design principles & tips for successful draws. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped cup or cylinder. Deep draw stamping excels in producing intricate, deep, and complex shapes that might be challenging for. Web from start to finish, the deep draw stamping process is as follows: Successful deep drawing depends on many factors. The material is actually forced into a plastic state as it is dragged over the die radius and down This method often results in less waste, as the metal is stretched and formed rather than cut away. Our engineers review the part design in detail to ensure it is appropriate for deep drawn stamping. The material is actually forced into a plastic state as it is dragged over the die radius and down Forcing part of the components diameter to extend from the original shape. What are the types of deep drawing processing? Prospect machine products deep draw metal stamping. Finishing processes our finishing options include: The most prominent benefit is that the unit cost is decreased considerably when unit count increases. Successful deep drawing depends on many factors. Forcing part of the components diameter to extend from the original shape. Web welcome to our deep draw shop. In other words, once the die is created, mass production can create large volumes of products. Web deep draw metal stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. Our engineers review the part design in detail to ensure it is appropriate for deep drawn stamping. The most prominent benefit is that the unit cost is decreased. Web producing a wide variety of deep draw metal stampings. Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. Here at pmp, we tailor our deep drawing expertise in our metal. What are the types of deep drawing processing? Web advantages of deep draw stamping complex shapes: Web welcome to our deep draw shop. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Successful deep drawing depends on many factors. Deep drawn parts are found in countless applications for many industries including consumer. Prospect machine products deep draw metal stamping. Successful deep drawing depends on many factors. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Anatomy of deep drawn stamping. Web deep drawn stamping is typically used because it offers many advantages over traditional metal forming and manufacturing processes. Has been supplying deep drawn metal stampings and custom eyelets to a variety of industries for over 125 years and is committed to producing quality deep drawn parts on time, with dedicated service, at a fair price. Web these other forming. Cutting a round or shaped section of metal from the draw component. Web deep draw metal stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. In the bulging process a. Web deep drawn stamping process the process. Successful deep drawing depends. Has been supplying deep drawn metal stampings and custom eyelets to a variety of industries for over 125 years and is committed to producing quality deep drawn parts on time, with dedicated service, at a fair price. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. It’s the process of forming a. Web advantages of deep draw stamping complex shapes: In the bulging process a. The material is actually forced into a plastic state as it is dragged over the die radius and down Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions into a cavity, producing a closed bottom, round, or irregularly shaped. Deep draw stamping excels in producing intricate, deep, and complex shapes that might be challenging for. Web from start to finish, the deep draw stamping process is as follows: We consider the ideal thickness, shape, and radii of the finished part and what. Web deep drawn stamping is typically used because it offers many advantages over traditional metal forming and manufacturing processes. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Prospect machine products deep draw metal stamping. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. Web welcome to our deep draw shop. Aqueous cleaning, deburring, heat treating, and passivation. This method often results in less waste, as the metal is stretched and formed rather than cut away. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Examples of typical deep drawn components include cans, housings, and other containers. In the bulging process a. Web deep drawn stamping process the process. The stamping action in deep drawing is always accompanied by other metal forming techniques within the press. Web these other forming methods include:

What to Expect from Your Deep Draw Stamping Supplier

Deep Draw Stamping The Ultimate FAQ Guide CNstamping

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Hot Stamping and Prototype Stamping Duggan Manufacturing

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep Drawn Stamping Companies Deep Drawn Stamping Services

Deep Draw Metal Stamping Getting Started

Deep Draw Stamping D&H Industries

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Drawn Stamping Companies Deep Drawn Stamping Services

Anatomy Of Deep Drawn Stamping.

Web Deep Draw Stamping Metal Stamping Progressive Die Tooling Transfer Press Tooling Metal To Rubber And Metal To Metal Tooling For Diaphragms Custom Tooling To Meet Your Exact Specifications.

Web Although It Can Be Modified To Manufacture Particular Parts, Our Deep Drawn Stamping Process Typically Follows The Same Five Steps:

Forcing Part Of The Components Diameter To Extend From The Original Shape.

Related Post: