Deep Drawing Operation

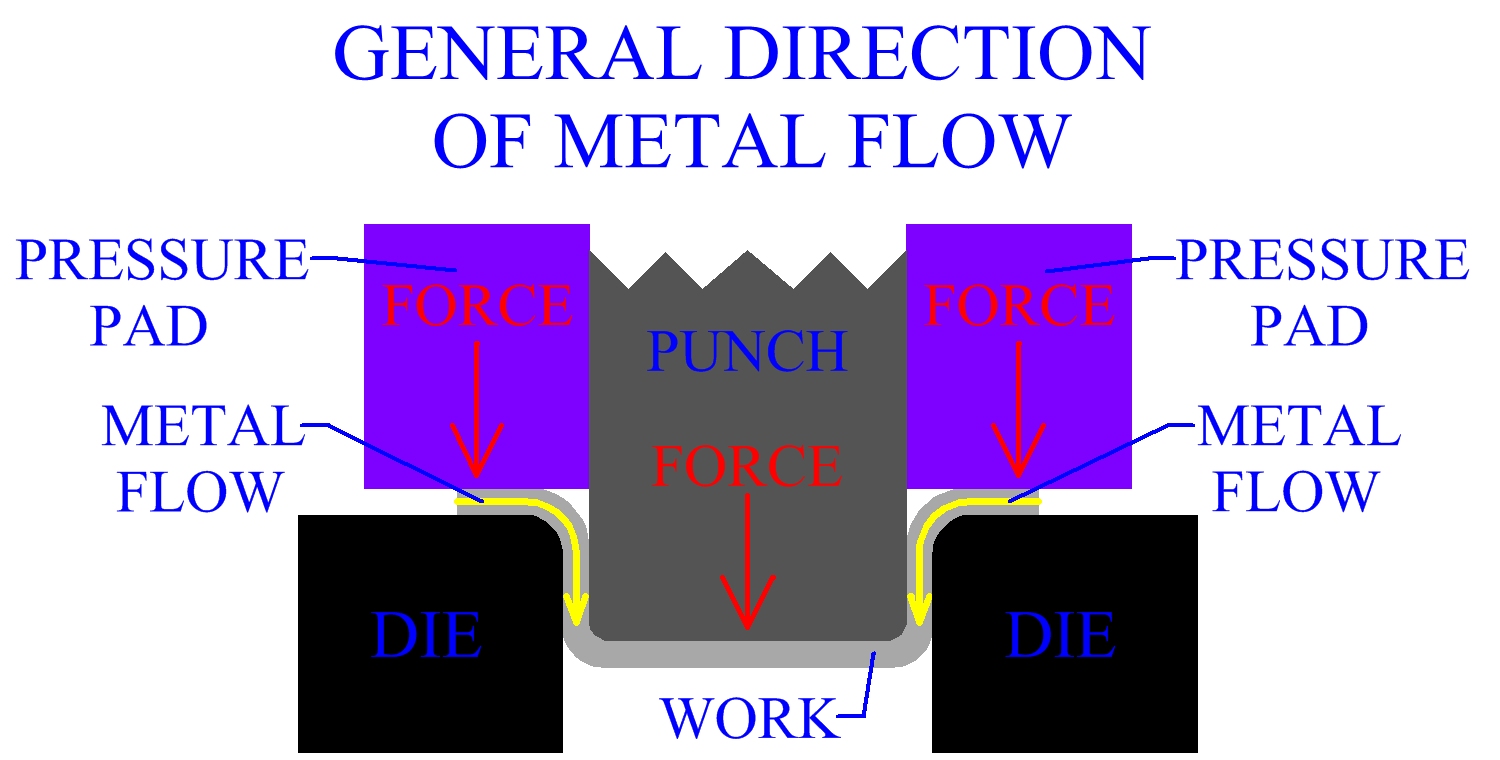

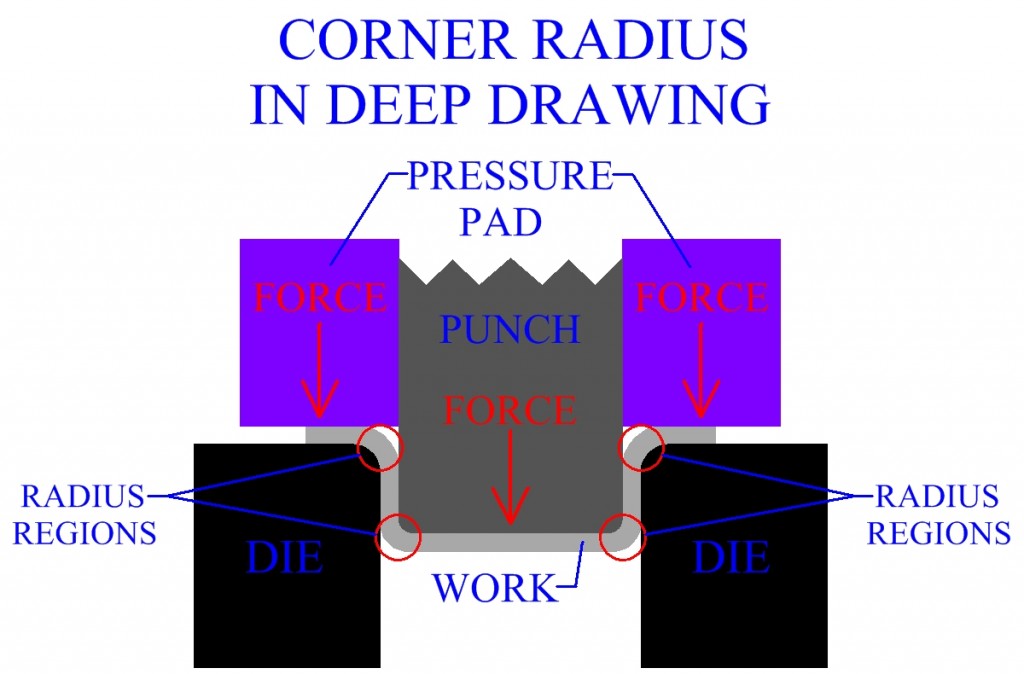

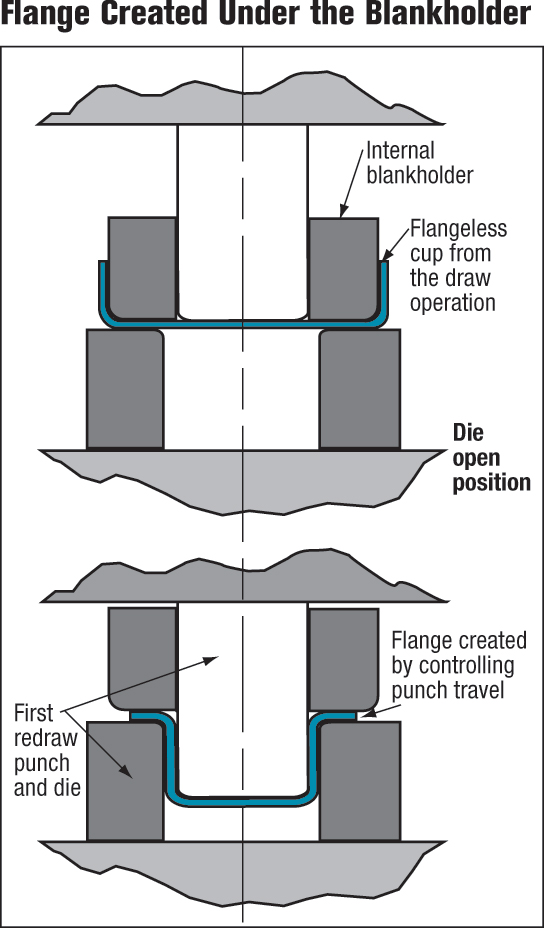

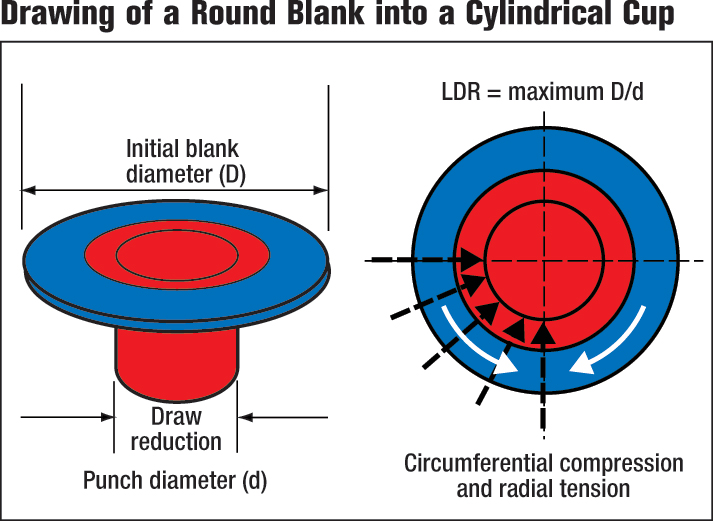

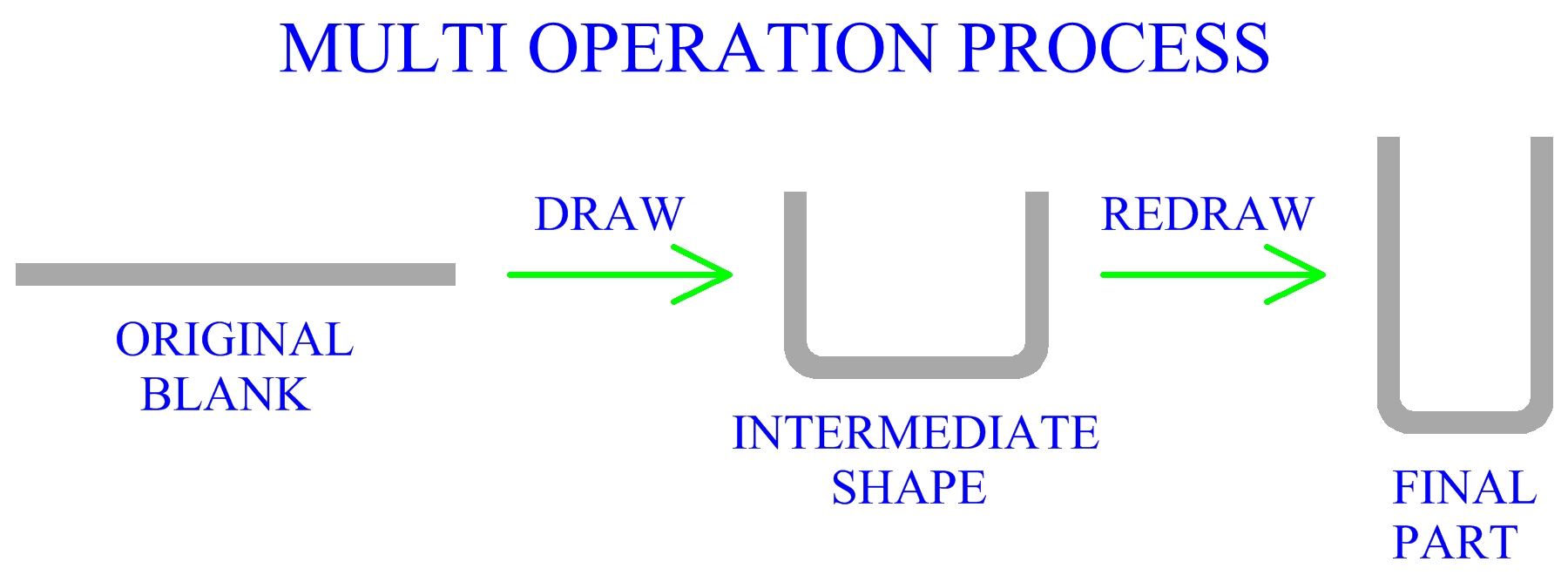

Deep Drawing Operation - Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. To the trained eye, the finished product can tell a very clear story about the quality of the process. Web these other forming methods include: The mold for deep drawing is been called deep drawing die. When compared to other metal forming. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Sheet metal deep drawing calculations. Deep drawing of sheet metals using the. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. The deep drawing process is often a combination of stretch forming and deep drawing. Web however, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. A round or shaped portion of metal is cut from the drawn part. Web the act of forcing metal into a. The typical tooling utilized in this process consists of a punch, die and blank holder. Deep drawing load and its components and their variations with punch movement. It is a versatile tool that can produce a wide range of products, including cooking pots, pans, automotive parts, and electrical enclosures. This operation involves placing a metal blank above a mold cavity. A round or shaped portion of metal is cut from the drawn part. Web deep drawing fundamentals of microforming. Web introduction deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. In the bulging process a. Pots and pans for cooking, containers, sinks, automobile parts, such as panels. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web the deep drawing process basically can be divided into three different kinds of load application (fig. (bandyopadhyay and panda, 2014 ). Web deep drawing fundamentals of microforming. This operation involves placing a metal blank above. Web deep drawing fundamentals of microforming. To the trained eye, the finished product can tell a very clear story about the quality of the process. It is a versatile tool that can produce a wide range of products, including cooking pots, pans, automotive parts, and electrical enclosures. Web however, regardless of the many factors involved, the most important element to. Web 1.1 deep drawing process. Types of deep drawing parts Compressive and tensile forces are used in the deep drawing operation to convert a. To the trained eye, the finished product can tell a very clear story about the quality of the process. Properties of work metal for optimal formability. When compared to other metal forming. Deep drawing using tools (most commonly used method), deep drawing using active media, and deep drawing by means of active energy. Now, with further increase of the load, the bent part of the blank is straightened in order to. The deep drawing process is often a combination of stretch forming and deep drawing. Specifically,. (bandyopadhyay and panda, 2014 ). Web these other forming methods include: Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. It is a blank / piece of sheet metal which is placed. The following are key elements affecting metal flow, and. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Now, with further increase of the load, the bent part of the blank is straightened in order to. When compared to other metal forming. The shape of product depends upon shape of punch. The deep drawing. To the trained eye, the finished product can tell a very clear story about the quality of the process. It is a blank / piece of sheet metal which is placed. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. Web deep drawing fundamentals of microforming. The typical tooling utilized in this. Now, with further increase of the load, the bent part of the blank is straightened in order to. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Deep drawing using tools (most commonly used method), deep drawing using active media, and deep drawing by means of active energy. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process. When compared to other metal forming. Web the act of forcing metal into a given shape introduces a host of possible problems and concerns. Web however, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Web process, diagram, advantages & applications. Web introduction deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. Following calculations are required during the design and manufacturing of. The typical tooling utilized in this process consists of a punch, die and blank holder. Deep drawing load and its components and their variations with punch movement. The metal thickness, the metal type, and the blank size. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing.

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

Deep drawing of sheet metal

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal TheMech.in

Deep Drawing from A to Z MetalForming Magazine Article

Deep Drawing from A to Z MetalForming Magazine Article

Deep Drawing Of Sheet Metal

Deep drawing operation sheet metal operation (part4) Tamil

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Sheet Metal Deep Drawing Calculations.

Web 1.1 Deep Drawing Process.

Web Pdf | On May 13, 2023, Araveeti C S Reddy Published Introduction To Deep Drawing | Find, Read And Cite All The Research You Need On Researchgate

Web Deep Drawing Operation In Sheet Metal Sheet Metal Deep Drawing Process.

Related Post: