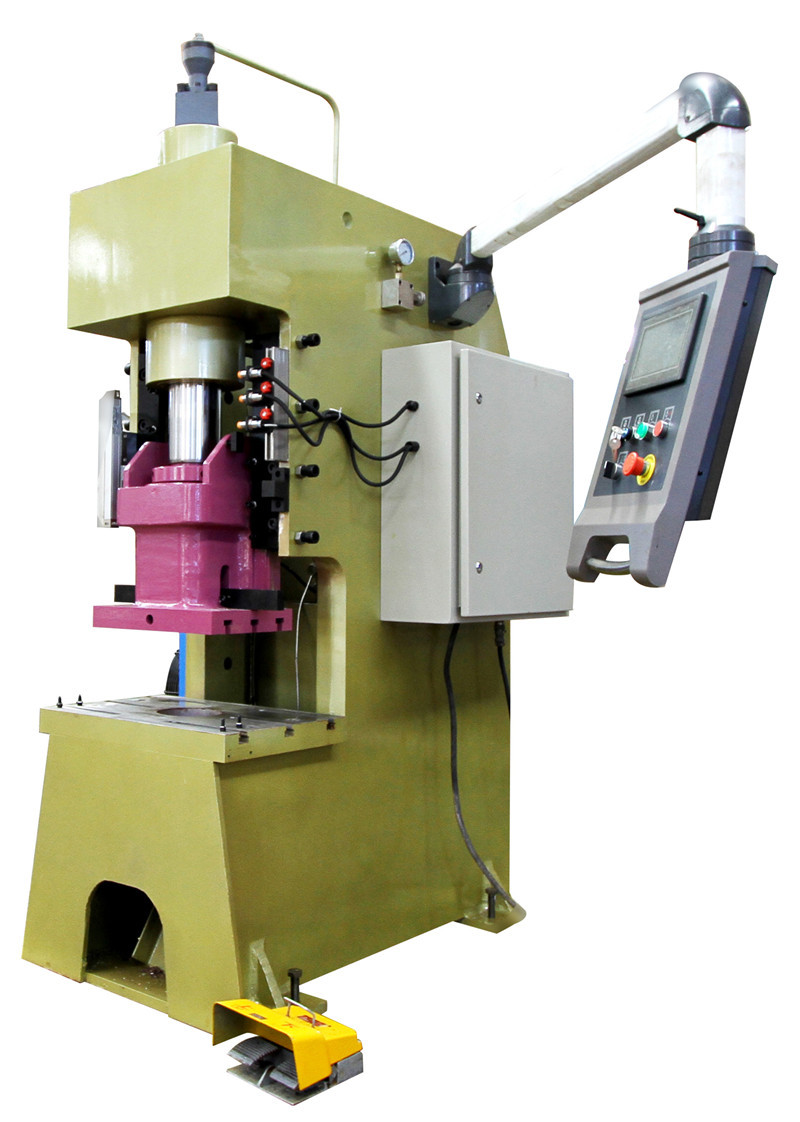

Deep Drawing Press

Deep Drawing Press - Focused on customer total cost of ownership, say company officials, engineers during press development paid close. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Gsj hydraulic press machine can forging, crush, straighten ,bending or mould metallic material. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. The repeatable and precise performance of our hydraulic deep draw presses offers the optimal process control required to form a wide array of parts reliably. Our deep drawing press allows for tonnage adjustments throughout the entire draw process, giving the operator complete control over material flow to eliminate wrinkling and tearing. Whether you are an illustrator, designer, web designer or just someone who needs to create some vector imagery, inkscape is for you! It is a versatile tool that can produce a wide range of products, including cooking pots, pans, automotive parts, and electrical enclosures. Web effective solutions for high precision deep draw press applications. Types of deep drawing parts We're one of the leading china hydraulic press manufacturers. Focused on customer total cost of ownership, say company officials, engineers during press development paid close. Pressure typically 800 bar (11,600 psi). Commonly found in aerospace, medical, and electronics manufacturing facilities, these machines are ideal for creating cans, boxes, and parts with curved flanges, which have. These hydraulic presses have a main upper cylinder and an hydraulic cushion in the lower part of the machine. This process is also known as hydraulic deep drawing press, hydraulic press machine drawing or simply, hydraulic drawing press. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have. Pressure typically 800 bar (11,600 psi). Web beckwood offers a range of deep drawing press features to improve the overall process including: The repeatable and precise performance of our hydraulic deep draw presses offers the optimal process control required to form a wide array of parts reliably. 3] if the ratio of height to diameter of the product is greater. The cycle time is depending on the tool size and the pressure level required, but normally range from 30 seconds to two minutes. Our deep drawing press allows for tonnage adjustments throughout the entire draw process, giving the operator complete control over material flow to eliminate wrinkling and tearing. Sheet hydroforming presses do complex draw work. This process is also. Focused on customer total cost of ownership, say company officials, engineers during press development paid close. These hydraulic presses have a main upper cylinder and an hydraulic cushion in the lower part of the machine. Sheet hydroforming presses do complex draw work. How a deep draw press works: Web our hydraulic deep drawing presses are designed with large table sizes. The mold for deep drawing is been called deep drawing die. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Web product description our standard deep drawing press ranges in tonnage from 45 to 1000 tons, features compact and intuitive design, function with either single. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. How a deep draw press works: Web our hydraulic deep drawing presses are designed with large table sizes and high speeds for great performances. Focused on customer total cost of ownership, say company officials, engineers during. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Gsj hydraulic press machine can forging, crush, straighten ,bending or mould metallic material. This process is also known as hydraulic. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Sheet hydroforming presses do complex draw work. Web hydraulic press deep drawing process. Ram and bed knockout / ejection options; Web shuntec's standard deep drawing press ranges in tonnage from 45 to 1000 tons and features a. The cycle time is depending on the tool size and the pressure level required, but normally range from 30 seconds to two minutes. Bed size, tonnage, stroke, speed, and more can be tailored to your specific draw forming application. Web goodsjack is professional manufacturer of deep drawing press machine, cold forging press, cnc hydraulic press according to your requirement. We're. Web product description our standard deep drawing press ranges in tonnage from 45 to 1000 tons, features compact and intuitive design, function with either single action or double action deep drawing process. This process is also known as hydraulic deep drawing press, hydraulic press machine drawing or simply, hydraulic drawing press. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Ram and bed knockout / ejection options; Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Web a powerful, free design tool. Web our hydraulic deep drawing presses are designed with large table sizes and high speeds for great performances. Web beckwood offers a range of deep drawing press features to improve the overall process including: It is a versatile tool that can produce a wide range of products, including cooking pots, pans, automotive parts, and electrical enclosures. Focused on customer total cost of ownership, say company officials, engineers during press development paid close. Commonly found in aerospace, medical, and electronics manufacturing facilities, these machines are ideal for creating cans, boxes, and parts with curved flanges, which have a tendency to wrinkle and tear. Our deep drawing press allows for tonnage adjustments throughout the entire draw process, giving the operator complete control over material flow to eliminate wrinkling and tearing. Web deep drawing presses, especially in the aerospace and medical industries, require unparalleled accuracy and precision. Pressure typically 800 bar (11,600 psi). We're one of the leading china hydraulic press manufacturers. Web hydraulic press deep drawing process.

Hydraulic Deep Drawing Press, Deep Drawing Press, हाइड्रोलिक डीप

Indotech Automatic 60 Ton To 600 Ton Hydraulic Deep Drawing Press

High speed deep drawing Hydraulic press machine Ma'anshan Prima CNC

Deep Drawing Press Deep Drawing Hydraulic Press Lexson Machinery

SemiAutomatic Iron Hydraulic Deep Drawing Press, ID 6761095173

Deep Drawing Press for LPG Cylinders ROK Teknik

Deep Drawing Presses Profi Press High Quality Hydraulic Presses!

Deep Drawing Press Deep Drawing Hydraulic Press Lexson Machinery

Deep Drawing Hydraulic Presses, Manufacturer, Exporter, India

Servo Double Action Deep Drawing Press China Hydraulic Press Machine

Web Shuntec's Standard Deep Drawing Press Ranges In Tonnage From 45 To 1000 Tons And Features A Compact And Intuitive Design.

The Repeatable And Precise Performance Of Our Hydraulic Deep Draw Presses Offers The Optimal Process Control Required To Form A Wide Array Of Parts Reliably.

These Hydraulic Presses Have A Main Upper Cylinder And An Hydraulic Cushion In The Lower Part Of The Machine.

The Cycle Time Is Depending On The Tool Size And The Pressure Level Required, But Normally Range From 30 Seconds To Two Minutes.

Related Post: