Drawing Chamfer Callout

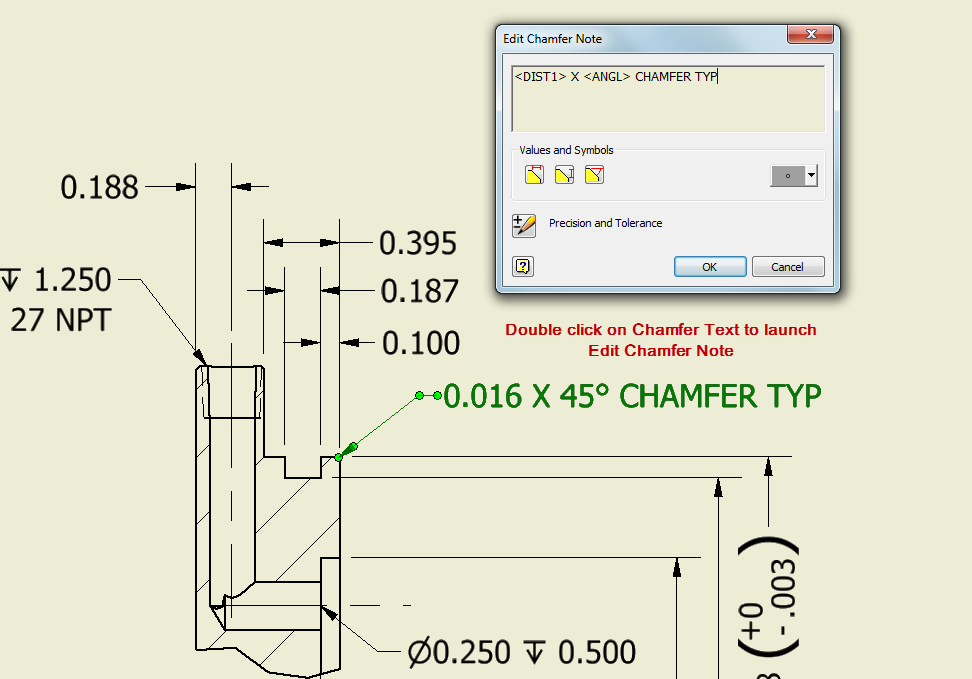

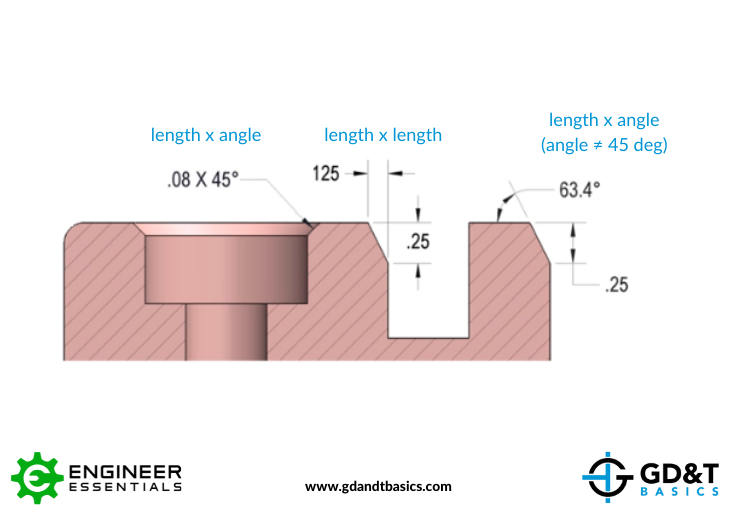

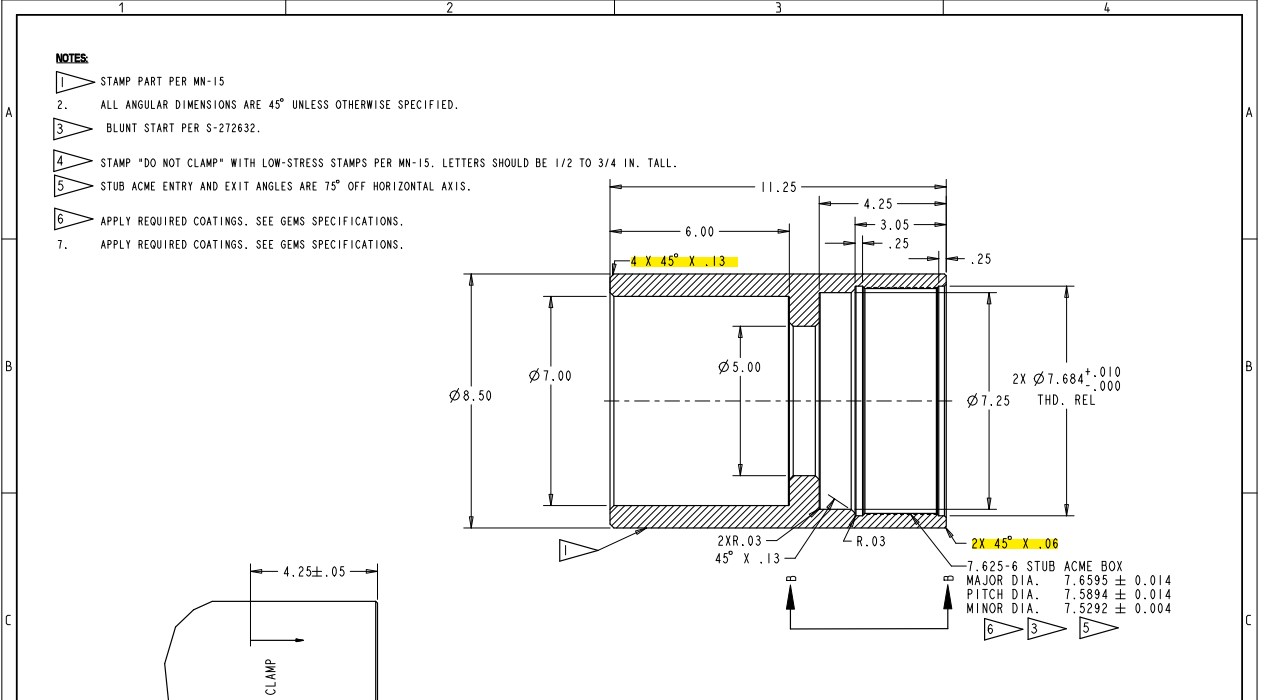

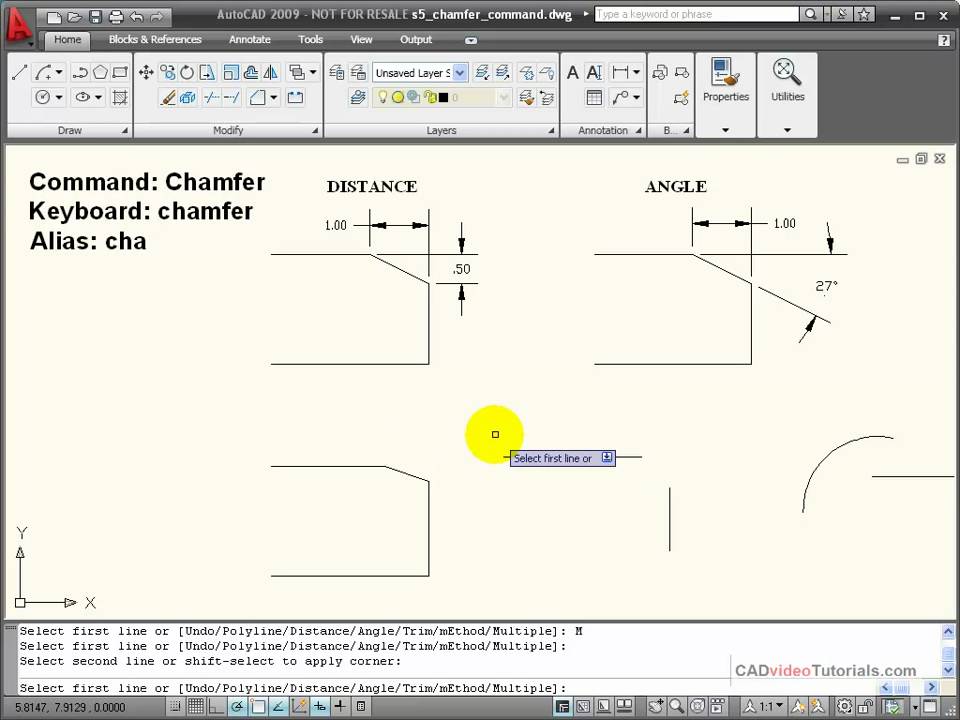

Drawing Chamfer Callout - See figure 2 for chamfer dimensioning examples. Web you can dimension chamfers in drawings. If you created the chamfer using the chamfer feature, simply show your dimensions for that feature or view. X display is the size of the x in a chamfer dimension with two numbers, such as 1 x 45° (length x angle), 45° x 1 (angle x length), 1 x 1 (length x length) or. After drawing the part, from the menu bar select design > solid > modify > chamfer. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. 4x r5, or r5 4x? If the selection was part of a hole feature, the precision, tolerance, fit class tolerance, and shaft class tolerance values from that feature are automatically applied. Web chamfers are also used on most mechanical elements such as shafts. The dimensioning of the chamfer is very simple on technical drawings. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. Is this correct or do i have it. For structural i have previously. Web a chamfer callout on this platform is straightforward with the steps as follows: Style 0 kudos reply notify moderator Web dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. Dimensions are required for points, lines, and surfaces that are related functionally or control relationship of other features. To continue from the aforementioned thread, how would i call out multiple chamfered corners? Style 0 kudos reply notify. X display is the size of the x in a chamfer dimension with two numbers, such as 1 x 45° (length x angle), 45° x 1 (angle x length), 1 x 1 (length x length) or. Is it customary to use a dash? Web you can dimension chamfers in drawings. In addition to the usual dimension display properties, chamfer dimensions. If no angle is given the chamfer is assumed to be at 45 degrees. They are created as slopes at the end of the round mechanical elements. Web introduction dimensioning refers to the addition of size values to drawing entities. Types, dimensions & callout this guide will help you to understand what is a chamfer and point out some differences.. If an angle other than 45 degrees is dimensioned, the surface to which the angle is measured must be made clear on the drawing. Chamfers can also be specified. Dimensions are required for points, lines, and surfaces that are related functionally or control relationship of other features. The dimensioning of the chamfer is very simple on technical drawings. Machining a. Select a circle that is part of a hole feature, or a thread that is part of an external thread feature. See figure 2 for chamfer dimensioning examples. You just need to give the length of one edge and the corresponding angle to it. In addition to the usual dimension display properties, chamfer dimensions have their own options for leader. Web dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. This opens the chamfer dialog box. See figure 2 for chamfer dimensioning examples. If an angle other than 45 degrees is dimensioned, the surface to which the angle is measured must be made clear on the drawing.. They are created as slopes at the end of the round mechanical elements. You just need to give the length of one edge and the corresponding angle to it. Basic dimensioning is the addition of only functional size values to drawing entities. Web you can dimension chamfers in drawings. Drag to place the callout. Style 0 kudos reply notify moderator If the selection was part of a hole feature, the precision, tolerance, fit class tolerance, and shaft class tolerance values from that feature are automatically applied. We will discuss how to measure it and how are chamfers dimensioned. Web solidworks course for beginners: From the chamfer dialog box, select the. We will discuss how to measure it and how are chamfers dimensioned. In addition to the usual dimension display properties, chamfer dimensions have their own options for leader display, text display, and x display. If it is not clear that a hole is a thru hole by looking at the drawing, then a depth or thru needs to be added. Web what is the correct way to call out a 45 degree chamfer? Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. I have been using this style for many years with multiple companies and drafting programs and have never questioned it. Web start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. Web chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. The feature being referenced is indicated through the use of a leader line. We will discuss how to measure it and how are chamfers dimensioned. Is it customary to use a dash? X display is the size of the x in a chamfer dimension with two numbers, such as 1 x 45° (length x angle), 45° x 1 (angle x length), 1 x 1 (length x length) or. Web november 21, 2021 by brandon fowler table of contents what is a break edge? In the conclusion, it will point out chamfering best practices. Web chamfers are also used on most mechanical elements such as shafts. Also, if you have multiple fillets, which format would be correct? Chamfers can also be specified. You just need to give the length of one edge and the corresponding angle to it.Solved 2D drawing chamfer dimmension type PTC Community

Dimensioning Chamfers YouTube

Adding a Chamfer Dimension YouTube

Dimensioning standards

Chamfer Dimensioning GD&T Basics

Drawing Dimension chamfer note tool Autodesk Community

Inventor Chamfer 메모에서 통화의 소수 자릿수를 변경할 수있는 기능 Inventor 제품 Autodesk

Solved Multiple chamfers on drawings PTC Community

AutoCAD Tutorial Using the CHAMFER Command YouTube

Introduction to AutoCAD Chamfer YouTube

Is There A Way To Change It ?

Types, Dimensions & Callout This Guide Will Help You To Understand What Is A Chamfer And Point Out Some Differences.

Click On The Links Below To Learn More About Each Gd&T Symbol Or Concept, And Be Sure To Download The Free Wall Chart For A Quick Reference When At Your Desk Or On The Shop Floor.

.040 X 30) To My Knowledge The.040 Be The Depth Into The Material And The 30 Degrees Is The Angle From The Centerline.

Related Post: