Drawing Manufacturing Process

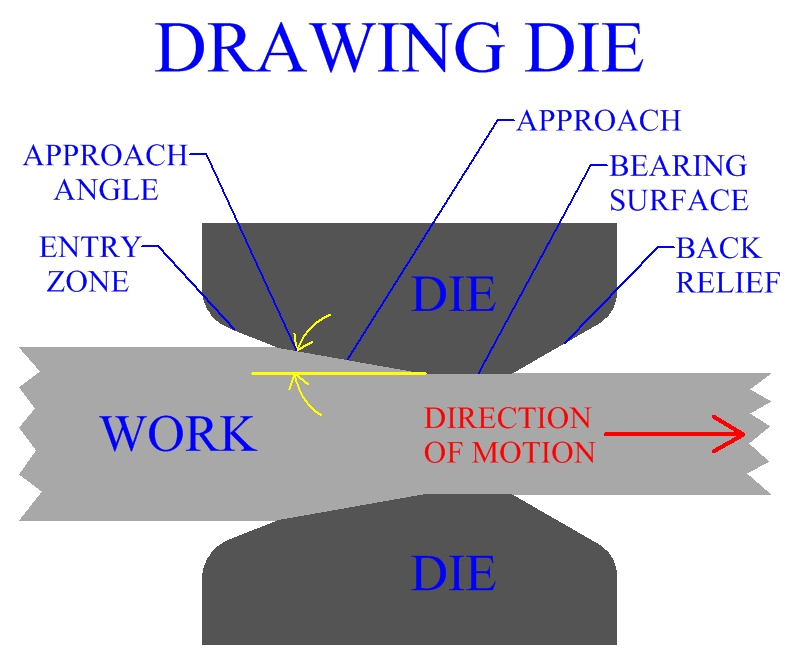

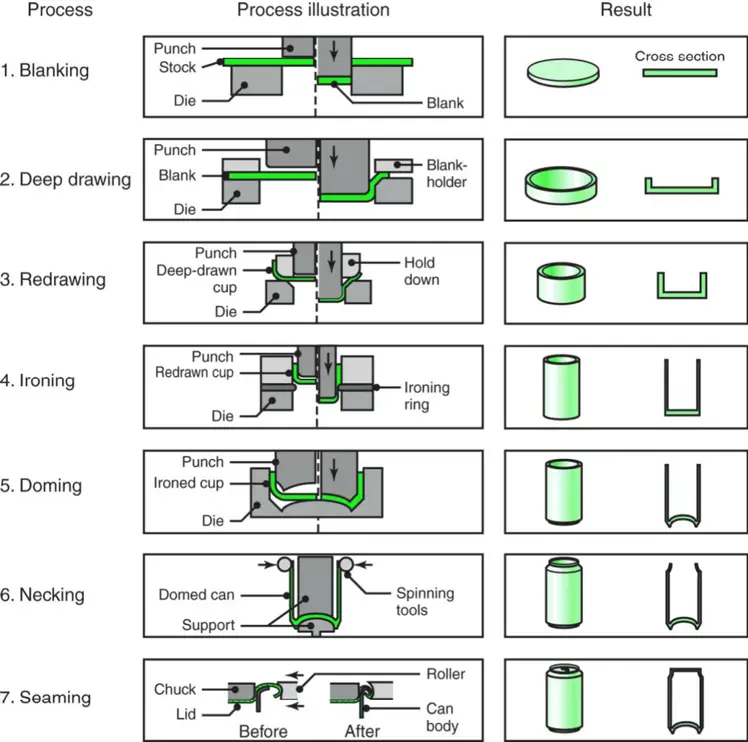

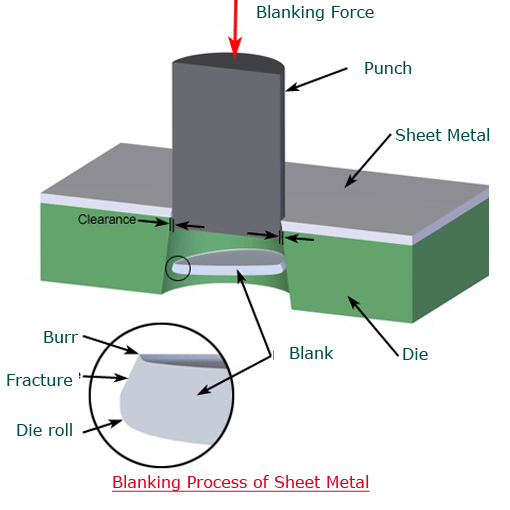

Drawing Manufacturing Process - The metal drawing process in manufacturing industry is usually performed cold. Appreciably increases strength and hardness of metal. According to interesting engineering, perspective drawing was invented in the 1300s. This is typically accompanied by a thinning out of the material, usually through a reduction in the girth. Swapna et al., [1] worked on the conventional deep drawing (cdd) operation at room temperature in industries which has serious difficulties because of the large number of. Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: What are the important/critical dimensions of the part? Each pair of rollers spins faster than the previous one. Web metal drawing metal drawing process. Web application of drawing manufacturing process one of the primary applications of drawing is manufacturing wires and cables. Wires and cables are used in various. The process involves pulling a billet of metal through a series of dies, reducing its diameter or thickness and shaping it into a product. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. This is typically accompanied by a thinning out of the material, usually. Web 1 the basics: Drawing, in yarn manufacture, process of attenuating the loose assemblage of fibres called sliver ( q.v.) by passing it through a series of rollers, thus straightening the individual fibres and making them more parallel. (a) move, (b) contact, and (c) withdraw micropipette from polymer solution droplet. Drawing is used to produce wires and cables with varying. Swapna et al., [1] worked on the conventional deep drawing (cdd) operation at room temperature in industries which has serious difficulties because of the large number of. As the metal stretches, it becomes longer and thinner. [1] it is thus a shape transformation process with material retention. The process is widely used for producing different products such as automotive parts,. Web drawing is a common metalworking process performed by manufacturing companies. The drawn fiber is linked to other formerly deposited polymer solution droplet and lead to formation of suspended fiber. For our purposes we’ve used solidworks, but the process can be easily replicated using other engineering drawing software. [1] it is thus a shape transformation process with material retention. Have. Drawing reduces a soft mass of fibre to a firm uniform strand. Web drawing is a metalworking process which uses tensile forces to stretch metal. For the communication of the final design for production purposes we use the types of drawings which are called working drawings or production drawings. Wires and cables are used in various. Deep drawing, or simply. The metal drawing process in manufacturing industry is usually performed cold. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web in this article, we will share techniques to ensure your drawing is comprehensive for any manufacturing process and can. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Metal drawing dies, in manufacturing industry, are usually made of cemented carbides or tool steels. Tube drawing is also similar. Drawing is classified in two types: What material does the part. Very complex parts can be achieved using deep drawing. What material does the part need to be made of to satisfy the design requirements (environment, strength, cost)? Web metal drawing metal drawing process. H ow accurat e d oes th e part need to be (tolerances)? It’s able to extend the length of metal by pulling and stretching the metal. Swapna et al., [1] worked on the conventional deep drawing (cdd) operation at room temperature in industries which has serious difficulties because of the large number of. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Have standardized sizes and parts been used where applicable? According. Wires and cables are used in various. Drawing reduces a soft mass of fibre to a firm uniform strand. It’s called “drawing” because the machine “draws” the metal towards it. What material does the part need to be made of to satisfy the design requirements (environment, strength, cost)? Web deep drawing may be a viable production solution for any manufacturing. As the metal is drawn (pulled), it stretches thinner, into a desired shape and thickness. Web nanofiber fabrication by drawing technique. Appreciably increases strength and hardness of metal. Drawing is classified into two types: Large quantities of products are easily manufactured through deep drawing complex. The metal drawing process in manufacturing industry is usually performed cold. For our purposes we’ve used solidworks, but the process can be easily replicated using other engineering drawing software. As the metal stretches, it becomes longer and thinner. Wire drawing is an cold working process. Web a drawing manufacturing process is vital in producing various metal products, including rods, tubes, sheets, and profiles. Deep drawn parts are created from a single sheet of metal rapid cycle times: Web how is the part going to be made? Web application of drawing manufacturing process one of the primary applications of drawing is manufacturing wires and cables. 2d drawings in manufacturing 2 the basics: This technique is instrumental in the production of a diverse range of items we frequently encounter, be it in household goods or specialized industrial equipment. Web drawing is a manufacturing process for producing a wire, bar or tube by pulling on a material until it increases in length.

Drawing Processes

Drawing Processes in Manufacturing

What is Deep Drawing Process? Mech4study

Metal Forming Basic, Types , Diagram , Classification Learn

32 Basic sheet metalworking operations (a) bending, (b) drawing and

Drawing (Manufacturing) Industries Process Engineering

Metal Drawing

Sheet Metal Drawing Process Bornmodernbaby

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Sheet Metal Fabrication Process SPS Ideal Solutions Blog

Web Drawing Is A Metalworking Process Which Uses Tensile Forces To Stretch Metal.

The First Technical Drawings For Manufacturing Were Perspective Drawings Of Real Objects.

Web Sheet Metal Drawing, A Crucial Manufacturing Process, Stands As A Cornerstone In The Creation Of Hollow, Multifaceted Components With A Sharp Focus On Precision.

Sheet Metal Drawing And Wire, Bar, And Tube Drawing.

Related Post: