Lubrication For Ball Bearing Drawer Slides

Lubrication For Ball Bearing Drawer Slides - Here are the steps for both options: I could squirt some oil into each, but i think it would end up making a mess and would attract dust, etc. Just a quick tip on silicone spray. Computer keyboard or pencil drawer. Some feature a tab on the drawer track that you can depress to release the track. Web dampen a microfiber cloth with mineral oil and rub the microfiber cloth along the slides and over the ball bearings several times. Keep in mind that dust is attracted to the grease option and. Replacing the drawers is pretty straight forward, remove old, install new, and ensure the adjustment is perfect. Web do ball bearing drawer slides need to be lubricated? However, this is also dependent on the usage and environment. Web #1 i have about 50 drawer slides (in stanley vidmars) that are in need of lubrication. To lubricate your drawer slides, apply a small amount of lubricant to the slides and the rollers or. Here are the steps for both options: Over time the drawer system will need a bit more grease. Keep in mind that dust is attracted. Learn how to clean, maintain, and lubricate your slides to restore their original performance. In this post, we’ll explore the best lubricant for tool box drawer slides and give you our verdict on. Here's where to put it! Load capacity of 35 lbs (16 kg) per pair. 32mm hole pattern with direct access mounting. To do so, carefully pull it straight out to slide it off of the runners. The slide is already lubricated enough for normal slide life. To lubricate your drawer slides, apply a small amount of lubricant to the slides and the rollers or. Learn how to clean, maintain, and lubricate your slides to restore their original performance. The slides are. Web first, clean and lubricate metal drawer slides and ball bearings using the best lubricant for metal drawer slides; Some feature a tab on the drawer track that you can depress to release the track. They have open bearings, and it appears that originally they were greased. 32mm hole pattern with direct access mounting. Web dampen a microfiber cloth with. Web without proper lubrication, the slides may stick, creating unnecessary wear and tear on the slides and the drawer. Web dampen a microfiber cloth with mineral oil and rub the microfiber cloth along the slides and over the ball bearings several times. Reunite the assembly later on. Tool box slides are important for many reason. Here are the steps for. Web first, clean and lubricate metal drawer slides and ball bearings using the best lubricant for metal drawer slides; Web july 3, 2022 by branon ramos. Over time the drawer system will need a bit more grease. Includes 1 slide, 1 rear bracket, 2 plastic tacks and screws In this post, we’ll explore the best lubricant for tool box drawer. To make it convenient for you, we have compiled a quick guide defining the process of cleaning and lubricating kitchen cabinets and drawer slides. Web first, clean and lubricate metal drawer slides and ball bearings using the best lubricant for metal drawer slides; Web drawer slide replacement steps. 32mm hole pattern with direct access mounting. Here's where to put it! The best thing about silicone is they don't. They have open bearings, and it appears that originally they were greased. I could squirt some oil into each, but i think it would end up making a mess and would attract dust, etc. Web dampen a microfiber cloth with mineral oil and rub the microfiber cloth along the slides and over. But when it comes to lubricating drawer slides, which lubricant is the best? Reunite the assembly later on. Here's where to put it! 32mm hole pattern with direct access mounting. Dab it in a wheel bearing or universal joint grease and apply along your slide’s raceways. Reunite the assembly later on. Web without proper lubrication, the slides may stick, creating unnecessary wear and tear on the slides and the drawer. The detachment method varies widely by manufacturer. The best thing about silicone is they don't. In addition, coat the other rails with mineral oil. Some feature a tab on the drawer track that you can depress to release the track. Web #1 i have about 50 drawer slides (in stanley vidmars) that are in need of lubrication. They have open bearings, and it appears that originally they were greased. Follow these drawer slide replacement instructions step by step to make replacing your drawer slides a breeze. Here's where to put it! Web drawer slide replacement steps. The best thing about silicone is they don't. Includes 1 slide, 1 rear bracket, 2 plastic tacks and screws Here's where to put it! Load capacity of 35 lbs (16 kg) per pair. Just a quick tip on silicone spray. Web over time the drawer system will need a bit more grease. To do so, carefully pull it straight out to slide it off of the runners. The slide is already lubricated enough for normal slide life. Sometimes slides need additional greasing, especially if they have been cleaned. In this post, we’ll explore the best lubricant for tool box drawer slides and give you our verdict on.

ball bearing drawer slide lubrication gaysexinvan

ball bearing drawer slide lubrication elcapitanvanhorn

Top 10 Best Lubricant For Tool Box Drawer Slides To Buy Online

ball bearing drawer slide lubrication gaysexinvan

ball bearing drawer slide lubrication iphone7pluswallpaperrickandmorty

6 Pair of 14 Inch Full Extension Heavy Duty Drawer Slides,Lubrication

ball bearing drawer slide lubrication elcapitanvanhorn

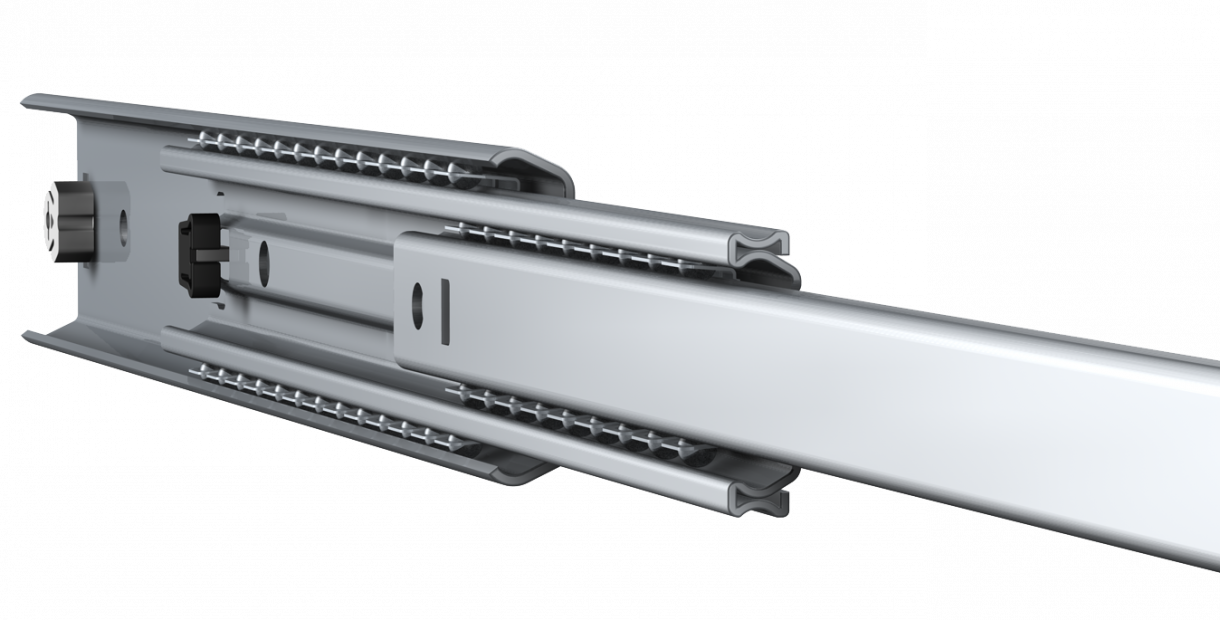

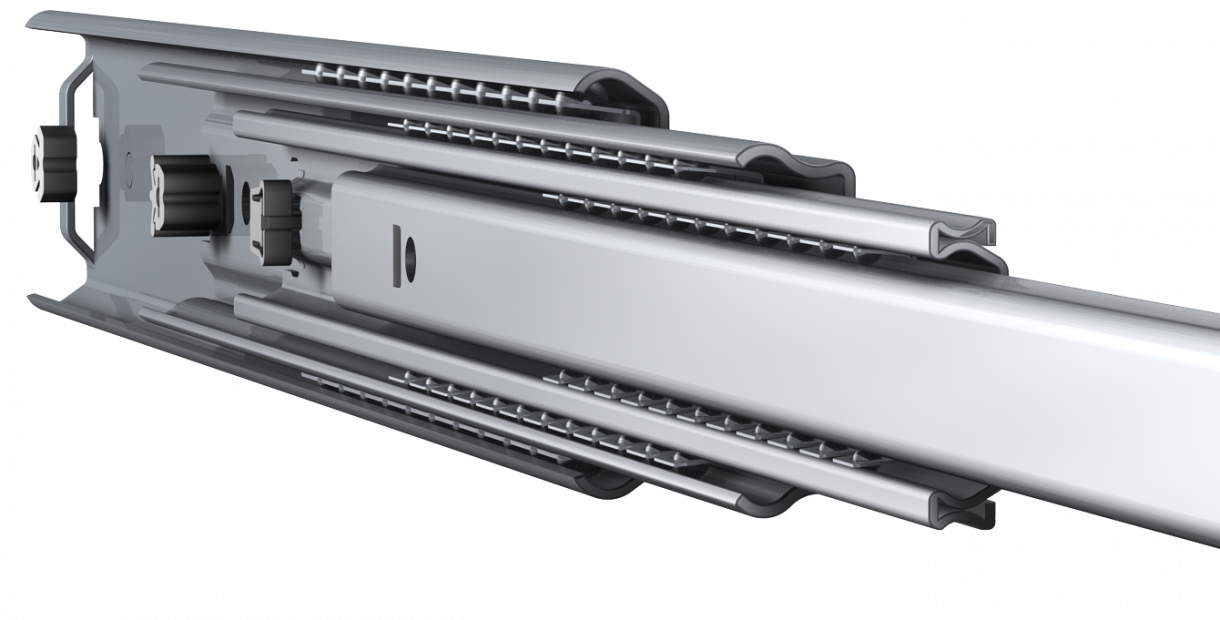

Ball Bearing Drawer Slides Drawer Runners & Door Slides Unico

ball bearing drawer slide lubrication elcapitanvanhorn

ball bearing drawer slide lubrication howtostylechunkybootswhite

Learn How To Clean, Maintain, And Lubricate Your Slides To Restore Their Original Performance.

The Detachment Method Varies Widely By Manufacturer.

You Might Have To Lift It Up Slightly At The End To Fully Detach It.

Dab It In A Wheel Bearing Or Universal Joint Grease And Apply Along Your Slide’s Raceways.

Related Post: