Section Line In Engineering Drawing

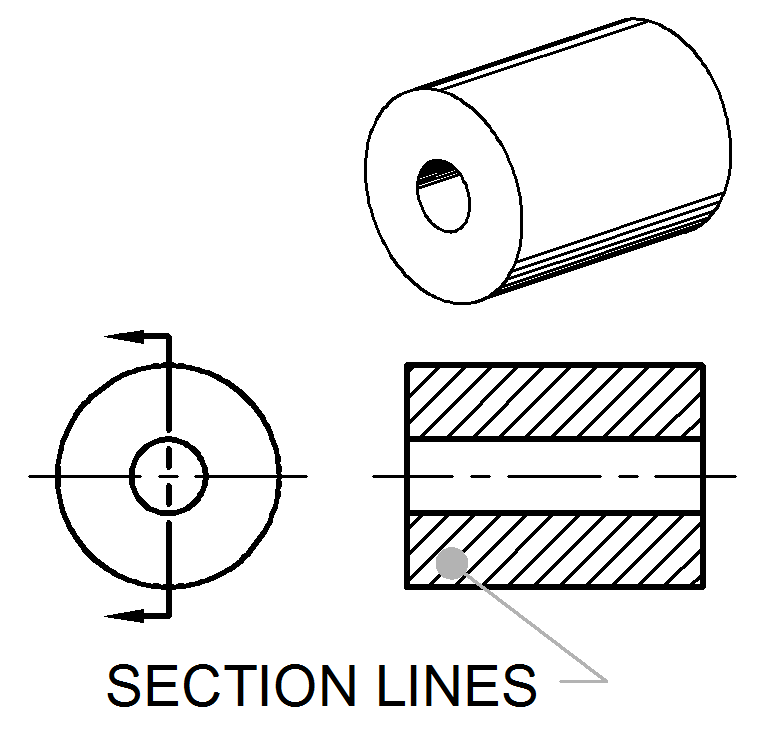

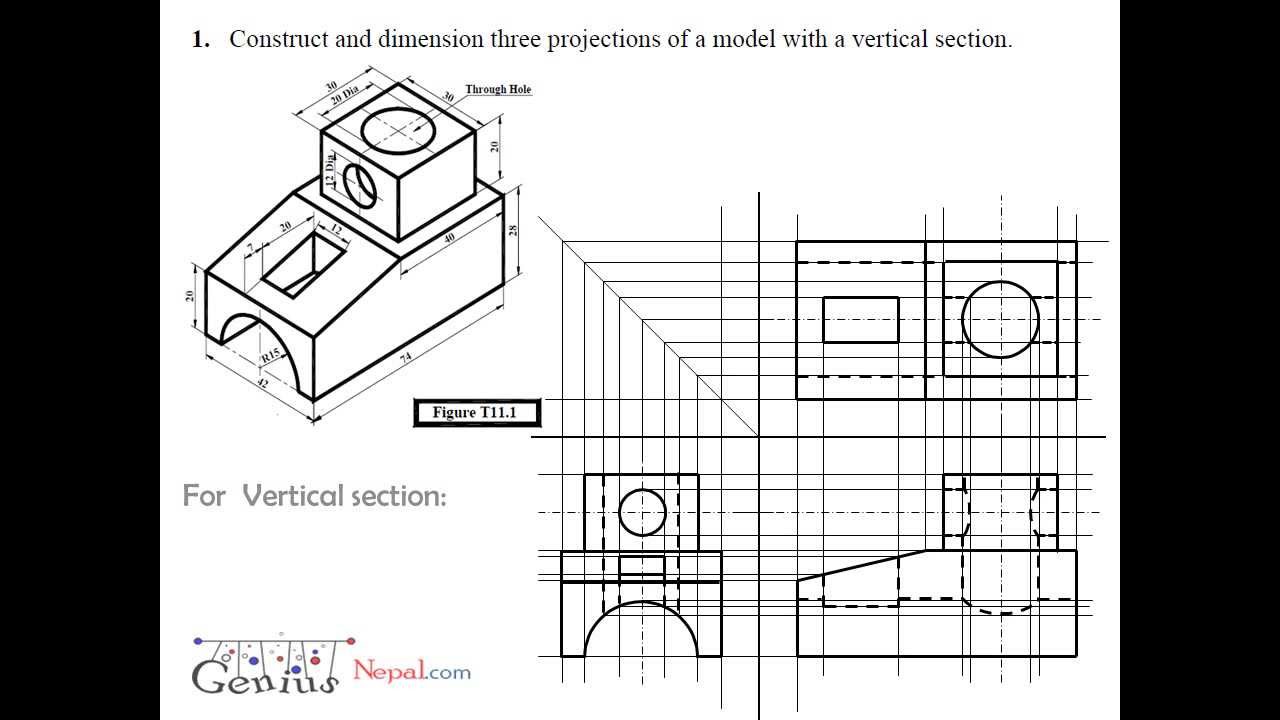

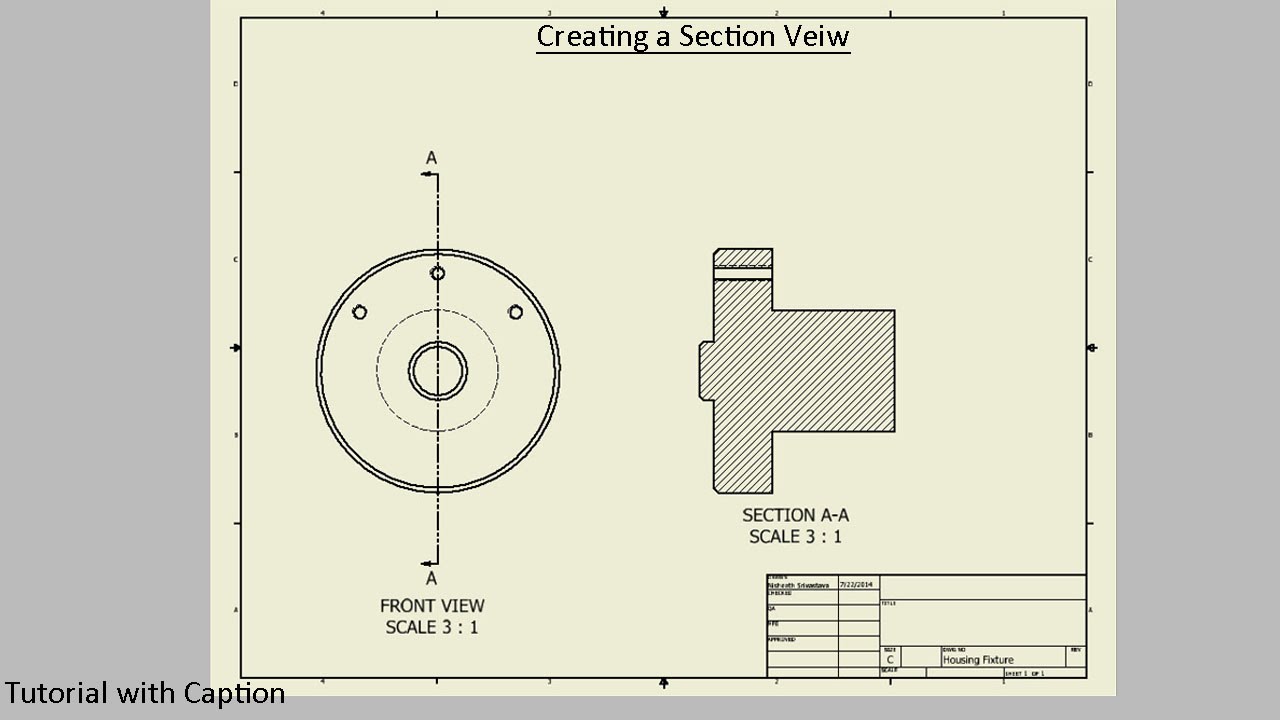

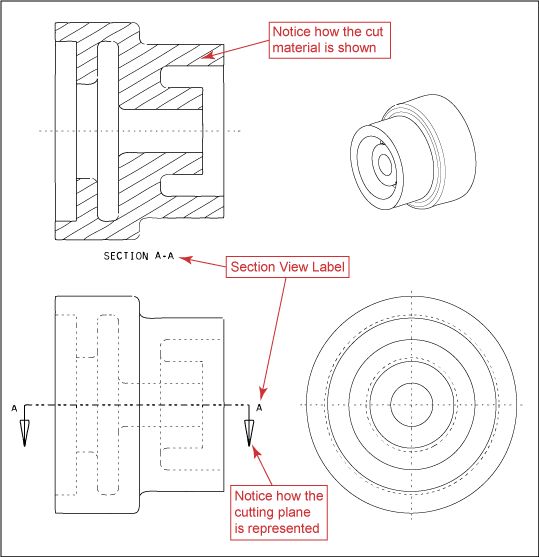

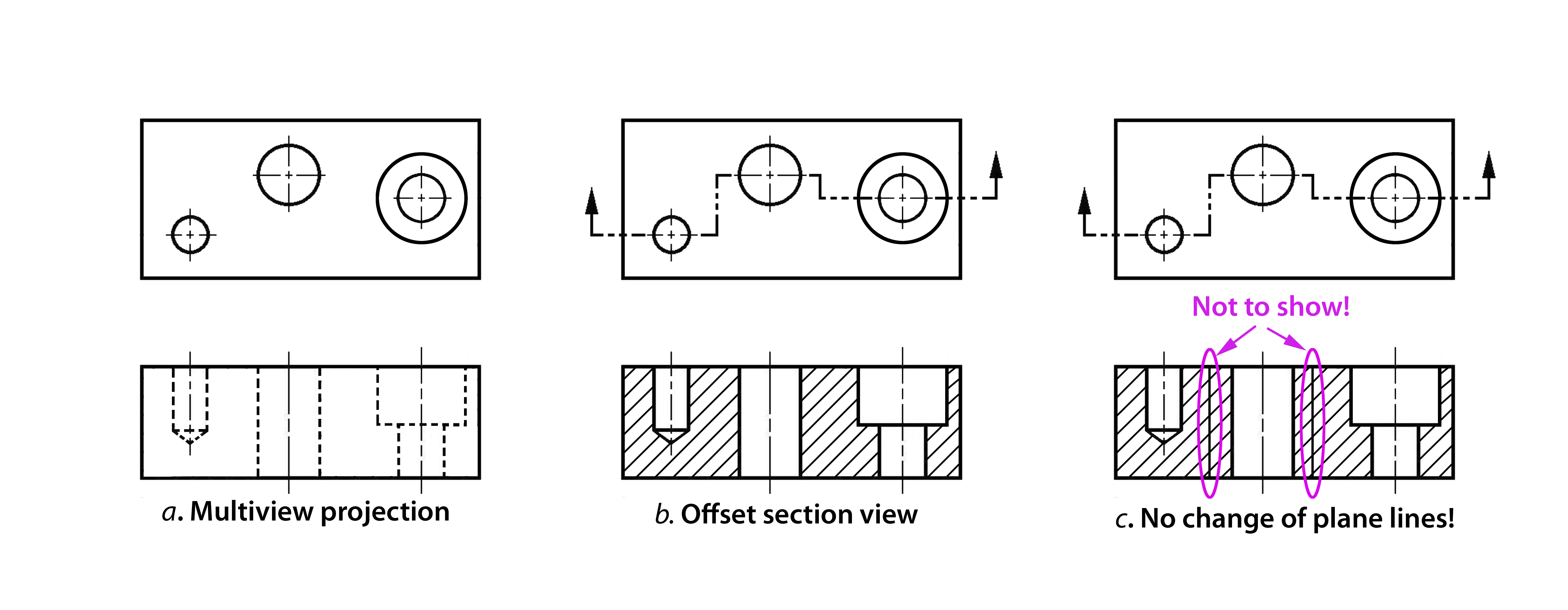

Section Line In Engineering Drawing - Web sectioning in technical drawing involves the use of cutting lines, section lines, and section symbols. This makes understanding the drawings simple with little to no personal interpretation possibilities. Web section lining is a method of representing internal features of an object in an engineering drawing. Click the 'create section' tool in your cad software, and the object will be sectioned: Web an engineering drawing is a type of technical drawing that is used to convey information about an object. Web and this is my friend, how you create a section view on the engineering drawing. Web the surface of the imaginary cut is crosshatched with lines called section lines. The diagonal lines in a section view are called 'hatching. Phantom lines are used to represent a movable feature in its different positions. Web the cut surfaces are identified by drawing section lines and the view thus obtained is called the “sectional view” or “view in section” of the remaining object. Usually, a number of drawings are necessary to completely specify even a simple component. Phantom lines are used to represent a movable feature in its different positions. Engineering drawings use standardised language and symbols. Next, draw two section lines that start and end on the cutting line. Hidden lines are almost never shown on section views. This indicator will then generate a section view. For large parts, outline sectioning may be used to save time. All the visible edges behind the cutting plane should be shown. Half section a half section view means that you are only removing a quarter of an object. Sections normally comprise of two parts, firstly the section cut indicator with identification. “drawing” usually means using drawing instruments, from compasses to computers to bring precision to the drawings. Web section lines are generally drawn at a 45° angle. All the visible edges behind the cutting plane should be shown. Phantom lines are used to represent a movable feature in its different positions. The section lines in all areas should be parallel. Web sectioning in technical drawing involves the use of cutting lines, section lines, and section symbols. Web the section lines should be evenly spaced and of equal thickness, and should be thinner than visible lines also, do not run section lines beyond the visible outlines or stop them too short object lines in the section view. Usually, a number of. Web sectioning in technical drawing involves the use of cutting lines, section lines, and section symbols. These are used to define the location of the section plane. This type of view is ordinarily used when the object is symmetrical or if you only need to show a portion of a complex assembly. Web and this is my friend, how you. Web following are the different types of lines used in engineering drawing: They are found on most sectional views, and indicate the surface which has been exposed by the cutting plane. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Convert the section to 2d view if you. Web sectioning in technical drawing involves the use of cutting lines, section lines, and section symbols. Section lines, or hatching, that represent the cut surface usually consist of thin parallel lines, as shown below, drawn at an angle of approximately 45° to the principal edges or axes of the part. This type of view is ordinarily used when the object. Convert the section to 2d view if you wish (using the tools in your cad software). “sketching” generally means freehand drawing. Web types of lines in engineering drawing: They can be used for elements such as finishes,. Web an engineering drawing is a subcategory of technical drawings. They provide features that can not be seen in a. Lineweights are different thicknesses for line presentation. Web a section or cross section is a view generated from a part or assembly on a cutting plane or multiple cutting planes that reveals the outlines on the inside or assembly fits. “drawing” usually means using drawing instruments, from compasses to computers. Web the cut surfaces are identified by drawing section lines and the view thus obtained is called the “sectional view” or “view in section” of the remaining object. Web section lines are generally drawn at a 45° angle. Web section lines and symbols. Web the selection of the width of the line depends on the scale, size, and type of. Web you can draw the cutting plane line in a plan view if you need to: Web section lines and symbols. Web sectioning in technical drawing involves the use of cutting lines, section lines, and section symbols. Notice that the square hole in the object has no section lining, since it was not changed by sectioning. Web the section lines should be evenly spaced and of equal thickness, and should be thinner than visible lines also, do not run section lines beyond the visible outlines or stop them too short object lines in the section view. Convert the section to 2d view if you wish (using the tools in your cad software). To begin, draw a cutting line across the object you want to section. They can be used to represent distance,. These lines are typically represented by using hatching and can be used to represent various features of an object, such as angles, dimensions, and surfaces. They are dark and thick lines of any engineering design drawing. Section lines, or hatching, that represent the cut surface usually consist of thin parallel lines, as shown below, drawn at an angle of approximately 45° to the principal edges or axes of the part. Web the general purpose or cast iron section line is drawn at a 45 degree angle and spaced 1/16 (1.5mm) to 1/8 (3mm) or more depending on the size of the drawing, but can be changed when adjacent parts are in section. Also known as object lines, visible. Web following are the different types of lines used in engineering drawing: Hidden lines are almost never shown on section views. All the visible edges behind the cutting plane should be shown.

Section Lines ToolNotes

Full Sectioning Problem 2 Engineering Drawing 9.2 YouTube

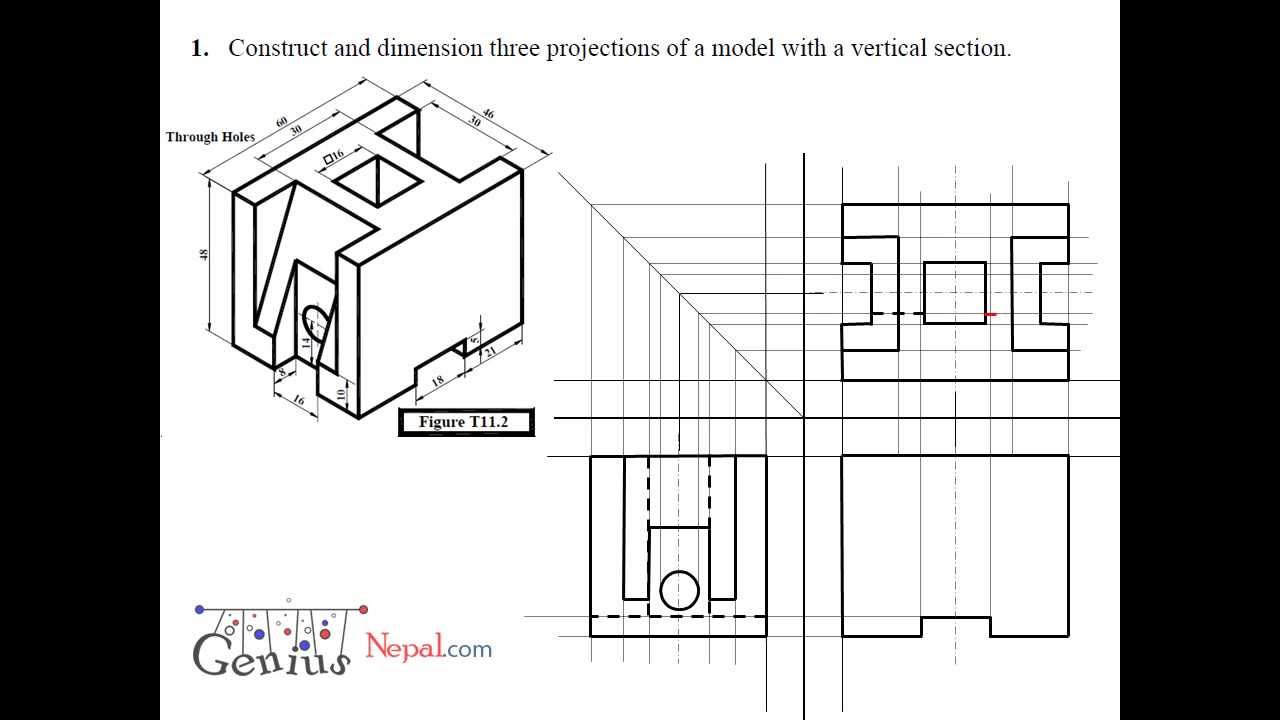

Engineering Drawing Tutorials/Orthographic and sectional views ( T 11

Engineering Drawing Tutorials/Orthographic and sectional views ( T 11.1

SECTION DRAWINGS BRANDON OWENS' PORTFOLIO

Sectional View Engineering Drawing Exercises at GetDrawings Free download

Sectional Views

Engineering Drawing Tutorials/Orthographic and sectional views ( T 11.2

SECTION DRAWINGS BRANDON OWENS' PORTFOLIO

Sectioning Technique Engineering Design McGill University

The Width Of The Line Should Be Chosen From One Of The Following.

Rules Of Sectioning Rule 1:

0.13 Mm, 0.18Mm, 0.25 Mm, 0.35 Mm, 0.50Mm, 0.70Mm, 1.0Mm, 1.4 Mm, And 2.0 Mm.

Usually, A Number Of Drawings Are Necessary To Completely Specify Even A Simple Component.

Related Post: