Thread Callout On Drawing

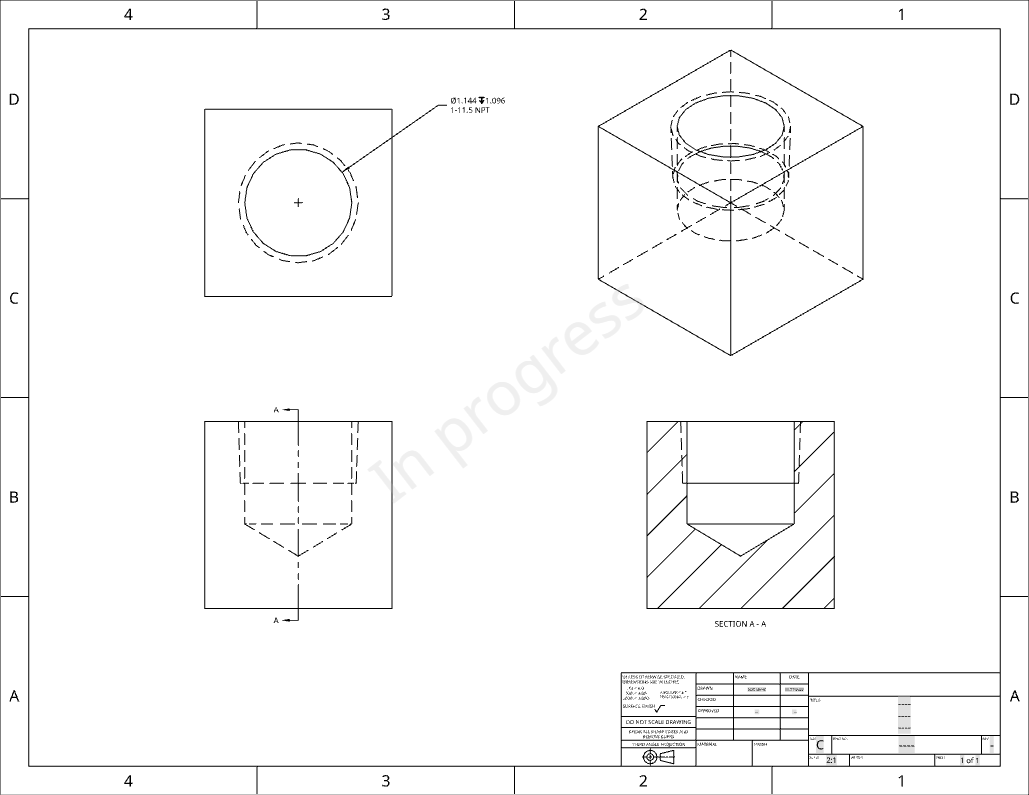

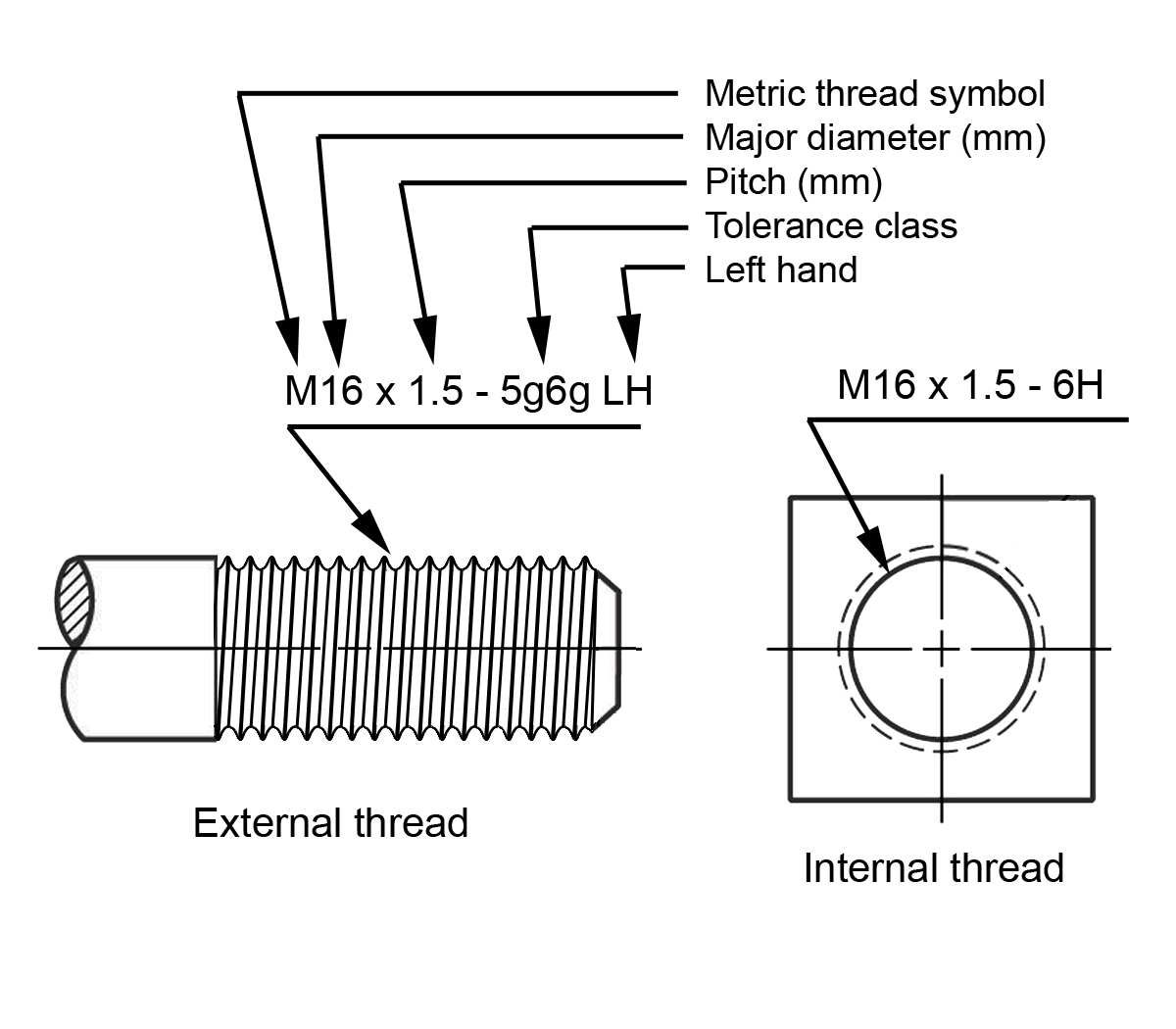

Thread Callout On Drawing - Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. Web threads are only symbolically represented on drawings; We can then use basic dimensions referencing the hole locations to datum planes b and c to define the holes’ true position. 6 local notes (callouts) 8 counterbore specification: Web here is my specific question about the two schools of thought, using a typical thread callout. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. Web cosmetic threads in part documents are inserted automatically into drawing views. Here are a few important things to remember when specifying threads: The callout basically corresponds to the length and diameter of the screw’s shaft. There are 3 parts for each callout. The callout basically corresponds to the length and diameter of the screw’s shaft. Local notes, also referred to as callouts, are included on a drawing to specify information for a specific feature of a component or assembly. M12 x 1.75 has a 12 mm major diameter and a 1.75. The first part represents the quantity of the hole. Therefore, thread. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. The callout basically corresponds to the length and diameter of the screw’s shaft. This corresponds to a ¼” nominal diameter thread with either 20 threads per inch or 28 threads per inch. There are 3 parts for each callout. The. Web threads are only symbolically represented on drawings; Here are a few important things to remember when specifying threads: The first time you see a callout can be a little confusing, but it’s pretty straightforward once you know what the numbers are meant to stand for. There are 3 parts for each callout. Inch thread and metric thread callout on. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. Web threads are only symbolically represented on drawings; We can then use basic dimensions referencing the hole locations to datum planes b and c to define the holes’ true position. Threads on tapped and tapered pipe tap holes are indicated. Web for example, a drawing has a thread callout of ¼”. The callout basically corresponds to the length and diameter of the screw’s shaft. Web cosmetic threads in part documents are inserted automatically into drawing views. Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. The first time you. Inch thread and metric thread callout on the engineering drawing. Web specification of metric threads: Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. An ansi drawing is illustrated below: The callout basically corresponds to the length and diameter of the screw’s shaft. The difference is one group says also call out diameter of the hole to be drilled to prepare for tapping, second group says don't include diameter of the hole, the thread callout handles it all. External thread notes are given in the longtitudinal view. 6 local notes (callouts) 8 counterbore specification: A thread callout is also inserted if the drawing. (you insert thread callouts in the cosmetic thread propertymanager, but they appear only in drawing documents.) thread callouts are not used in iso, jis, or other standards, but you can. A thread callout is also inserted if the drawing document is in ansi standard. There are 3 parts for each callout. We can then use basic dimensions referencing the hole. Web threads are only symbolically represented on drawings; Which is 3 in the case of inch thread and 2 in the case of metric thread from. The feature being referenced is Web creating a hole or thread callout: Web cosmetic threads in part documents are inserted automatically into drawing views. An ansi drawing is illustrated below: The option with fewer threads per inch is the coarse thread. Here are a few important things to remember when specifying threads: 6 local notes (callouts) 8 counterbore specification: The first time you see a callout can be a little confusing, but it’s pretty straightforward once you know what the numbers are meant to. A thread callout is also inserted if the drawing document is in ansi standard. When we look at a drill and tap chart, we see that there are two options for this size: External thread notes are given in the longtitudinal view. M12 x 1.75 has a 12 mm major diameter and a 1.75. There are 3 parts for each callout. 6 local notes (callouts) 8 counterbore specification: Web cosmetic threads in part documents are inserted automatically into drawing views. Specify threads on a 2d drawing with a thread specification callout (aka thread hole callout) for metric sizes, specify size with the thread pitch (diameter x pitch in mm); Web here is my specific question about the two schools of thought, using a typical thread callout. A thread note must be included on all threaded parts, with a leader line to the external thread or to an internal thread in the circular view. The first part represents the quantity of the hole. Which is 3 in the case of inch thread and 2 in the case of metric thread from. An ansi drawing is illustrated below: Local notes, also referred to as callouts, are included on a drawing to specify information for a specific feature of a component or assembly. The difference is one group says also call out diameter of the hole to be drilled to prepare for tapping, second group says don't include diameter of the hole, the thread callout handles it all. The image below depicts an ansi tapered pipe tap hole drawing:

How to Draw Threaded Hole in Autocad 2d Adkins Fricaunt

Hole/Thread Callout

Dimensioning threaded fasteners Engineering Design McGill University

Threaded Hole Callout Standard Home Interior Design

Thread callout in drawing Siemens UG/NX EngTips

3D Printing Threads (Cosmetic/Virtual Threads vs Real 3D Threads)

Using Cosmetic Threads in SOLIDWORKS Parts and Drawings

Using Cosmetic Threads in SOLIDWORKS Parts and Drawings

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems

Dimensioning threaded fasteners Engineering Design McGill University

The Feature Being Referenced Is

We Can Then Use Basic Dimensions Referencing The Hole Locations To Datum Planes B And C To Define The Holes’ True Position.

The Callout Basically Corresponds To The Length And Diameter Of The Screw’s Shaft.

Web Screws Come In A Wide Variety Of Shapes And Sizes, So Thread Callouts Are Used To Help Identify Them.

Related Post: