What Is Deep Drawing

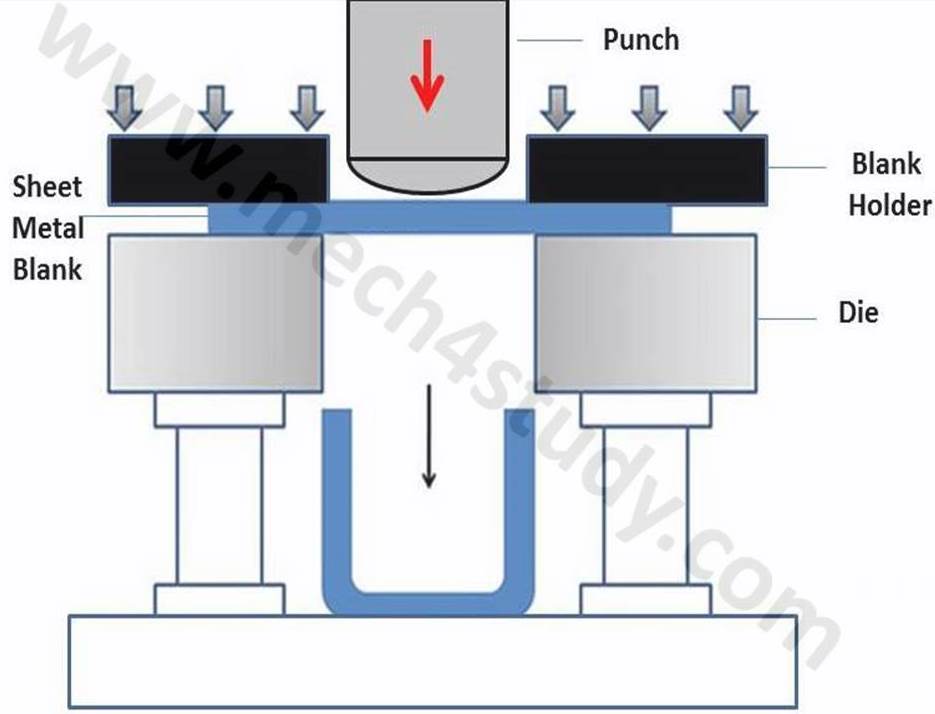

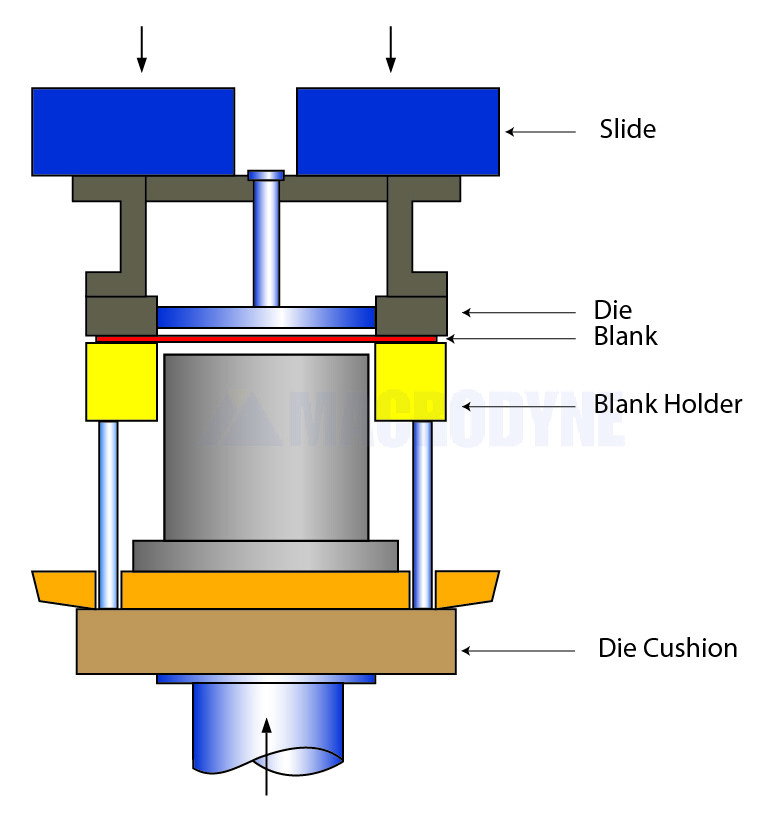

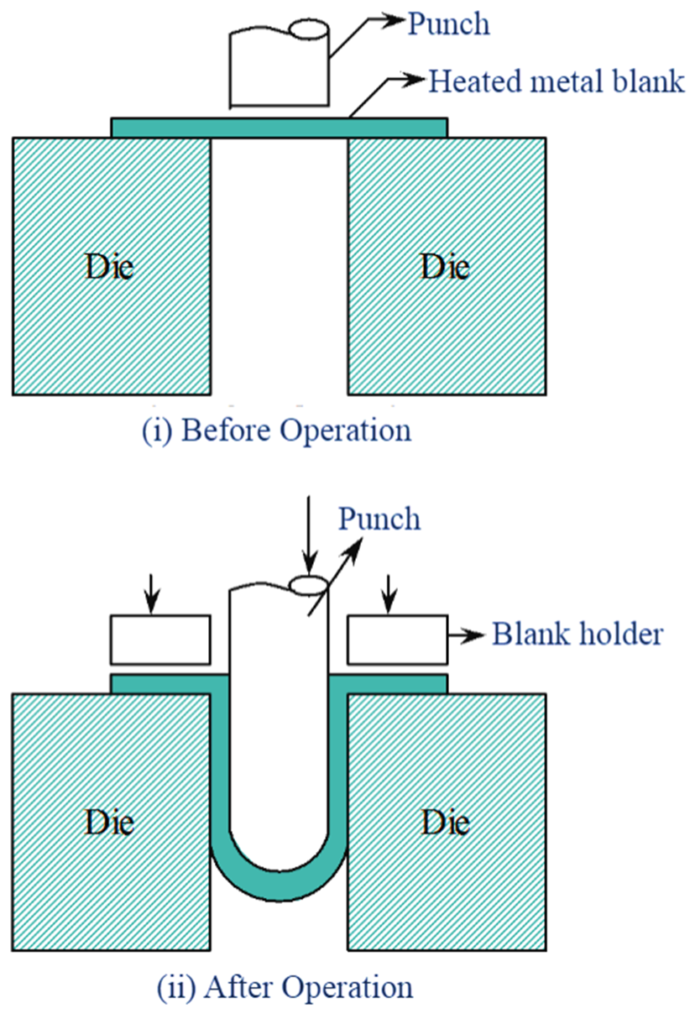

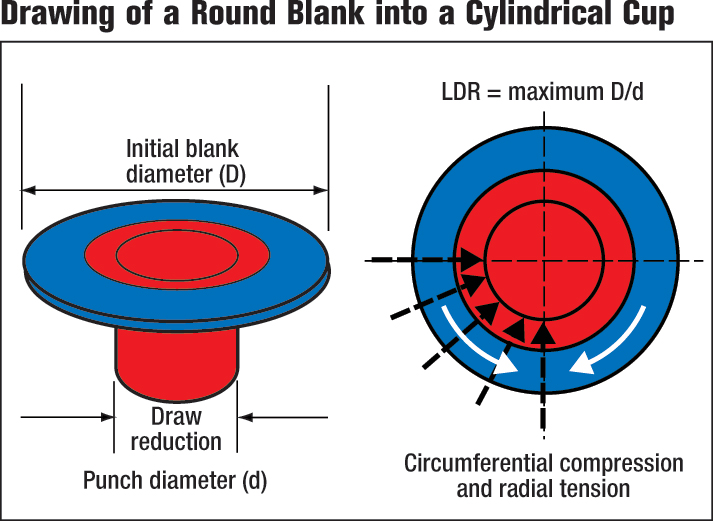

What Is Deep Drawing - The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. The deep drawing process is often a combination of stretch forming and deep drawing. Mhdd is a kind of sheet hydroforming method in which a. Examples of typical deep drawn components include cans, housings, and other containers. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. Web deep drawing is a sheet metal forming process that uses a punch and dies to draw (pull) the workpiece into the desired shape. The shape of product depends upon shape of punch. Benefits and industrial applications deep drawing process. Web what is deep drawing? Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Initially, the blank is heated to plastic state and it is placed over the die as shown in figure 1. Examples of typical deep drawn components include cans, housings, and other containers. Web deep drawing is a process of converting metal sheet into cylindrical. The sheet metal is placed between two dies, and the punch is forced against it to create the desired profile. Examples of typical deep drawn components include cans, housings, and other containers. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Web deep drawing fundamentals of microforming. The process is considered. It is a blank / piece of sheet metal which is placed. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die. [1] it is thus a shape transformation process with material retention. The process is considered deep drawing when the depth of the drawn part exceeds its diameter.. Web what is deep drawing? In most forming operations, stretching. Web deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing is a metal forming process whereby a flat sheet of metal is cold drawn or formed by mechanical or hydraulic. It is a blank / piece of sheet metal which is placed. Benefits and industrial applications deep drawing process. Deep drawing is a metal forming process whereby a flat sheet of metal is cold drawn or formed by mechanical or hydraulic presses into a seamless can. Examples of typical deep drawn components include cans, housings, and other containers. Web drawing. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Deep drawing is a metal forming process whereby a flat sheet of metal is cold drawn or formed by mechanical or hydraulic presses into a seamless can. Web deep drawing is a sheet metal forming process. In most forming operations, stretching. [1] it is thus a shape transformation process with material retention. This article highlights only the most frequently violated design and build principles. Deep drawing of sheet metals using the. Examples of typical deep drawn components include cans, housings, and other containers. Web deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. The deep drawing process is often a combination of stretch forming and deep drawing. The deep draw forming process begins with metal blanks. When the force is applied by the punch, the. The deep drawing process is a tensile compression technique used to create a metallic hollow body. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is. Although designing and building deep draw dies is fast becoming a science, the fundamental metal flow principles should never be ignored, for they are the foundations of a successful deep. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Benefits and industrial applications deep drawing process. Initially, the blank is heated to plastic. Deep drawing is especially beneficial when producing high volumes, since unit cost decreases. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed into a deep (often complex) shape, whereby the flat sheet is “drawn in” from the edges and “sucked in” to create a deep shape that otherwise may not be possible using normal metal forming techniques. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web deep drawing from a to z. The deep draw forming process begins with metal blanks. The deep drawing process is often a combination of stretch forming and deep drawing. The shape of product depends upon shape of punch. It is a blank / piece of sheet metal which is placed. Initially, the blank is heated to plastic state and it is placed over the die as shown in figure 1. The sheet metal is placed between two dies, and the punch is forced against it to create the desired profile. Web deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. Mhdd is a kind of sheet hydroforming method in which a. Web drawing is a process of forming flat sheet blanks into hollow shapes by means of a punch that causes the metal to be formed into the die cavity. Deep drawing of sheet metals using the. Web deep drawing is a sheet metal forming process that uses a punch and dies to draw (pull) the workpiece into the desired shape.

What is Deep Drawing Process? Mech4study

Deep Drawing 101 Macrodyne

Deep Drawn Methodology and Its Benefits

What is Deep Drawing? Process, Diagram, Advantages & Applications

Deep drawing of sheet metal

What is Deep Drawing Process? Mech4study

What is deep drawing? Mubion

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

Deep Drawing from A to Z MetalForming Magazine Article

best deep drawing process, by chris YouTube

Deep Drawn Parts Achieve Their Shape By Drawing Metal Into A Cavity Rather Than By Stretching Or Thinning Over A Die, So The Original Sheet Thickness Remains Essentially The Same From Start To.

Web Successful Deep Drawing Is A Combination Of Many Important Factors.

If The Depth Is One Or More Times The Diameter Of The Final Shape, Then The Process Is Called Deep Drawing.

Deep Drawing Of Irregularly Shaped Panels Constitutes One Of The Most Complex Metalforming Operations.

Related Post: